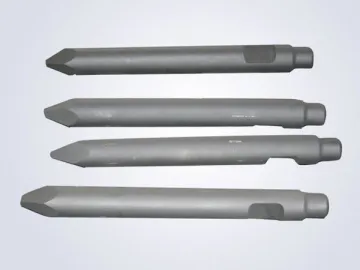

Cylinder

This hydraulic cylinder is specifically designed for use on the hydraulic breaker in mining industry. It is considered an important mining machinery part.

Mechanically strong, impact and rupture resistant, it's no wonder that 40Cr is the material of choice when it comes to constructing hydraulic breaker cylinders. The high-grade material, together with precision-machining technologies and great attention to detail, explains why our finished hydraulic cylinder could hold up to heavy duty tasks in the demolition of roads, concrete foundations, and high-rise buildings, let alone the light-duty job of breaking up hard rocks or granite. With steady, trouble-free performance, the cylinder is arguably the best bang for the buck anywhere anytime.

After over a decade of development, we have our abilities well honed to scratch build your breaker-specific cylinder from raw material procurement, through forging, precision machining and heat treating, to packaging and delivery as a seamless process. Many Chinese hydraulic breaker assembly factories have gradually learned to rely on us for their hydraulic cylinder solutions.

Process Flow

Lower Cylinder Body

1.Feeding →→ 2. Two-sided milling→→ 3.One-sided milling →→ 4.Pre-drilling →→ 5. Boring Machine →→ 6. NC milling machine →→ 7. Heat Treating

Upper Cylinder Body

1. Feeding→→ 2.Two-sided milling →→ 3. Pre-drilling →→4.Boring Machine →→ 5.NC milling machine →→6. Heat treating

The heat treating process is a complicated but crucial aspect of our manufacturing process. To give you a better idea of how each and every hydraulic breaker part is made, we offer you detailed process flow.

1. Preparation→→ 2. Surface cleaning →→ 3. Low-carbonworkpiece →→ 4. Feeding →→ 5.I. heating II. Carburizing →→ 6. Cooling→ → 7. Cleaning →→ 8. Process Inspection →→ 9. Annealing (Heating) →→ 10. Annealing (Cooling) →→ 11. Post-treatment →→ 13. Finished Component Inspection

Raw Material: ML40Cr(a kind of cold headed structural steel)

Standards: GB/T 6478-1986

Chemical Composition

1. C: 0.37~0.44(allowable variation:±0.01)

2. Si:≤0.30

3. Mn: 0.50~0.80 (allowable variation: ±0.02)

4. S: ≤0.035 P: ≤0.03

5. Cr: 0.80~1.10

6. Residual Nickel Content: ≤0.020

7. Residual Copper Content: ≤0.020

Mechanical Properties

Tensile Strength σb (MPa):≥1000

Yield Strength σs (MPa):≥981

Percentage Elongation δ5 (%):≥9

Reduction of Area ψ (%):≥45

Impact Toughness αkv (J/cm2):≥59(6)

Hardness: Annealing ≤207HB, Diameter of Indentation≥4.2mm

Heat Treating Conditions

Quenching Temperature: 850℃ (oil cooling)

Tempering Temperature: 520℃,(water cooling or oil cooling)

Construction Site Photos

Links:https://globefindpro.com/products/75878.html

-

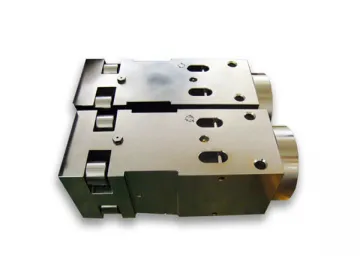

DCS50HFA Weigh Filler for Powder

DCS50HFA Weigh Filler for Powder

-

NTHSD-510 VFFS Machine with Reciprocating Jaw

NTHSD-510 VFFS Machine with Reciprocating Jaw

-

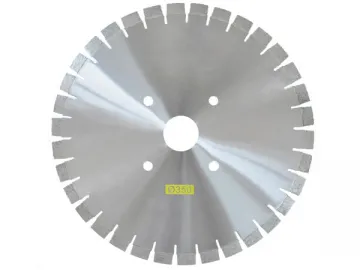

Granite Diamond Blade

Granite Diamond Blade

-

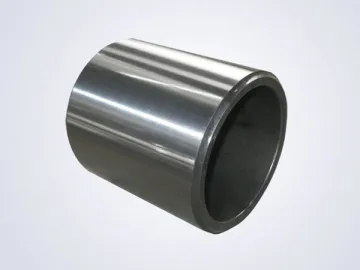

Bushing

Bushing

-

Bag Filling and Sealing Machine

Bag Filling and Sealing Machine

-

NTHSC-560 VFFS Machine with Rotary Jaw

NTHSC-560 VFFS Machine with Rotary Jaw

-

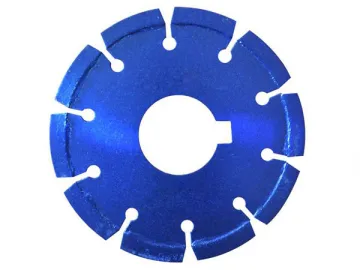

Diamond Blade for Grooving Machine

Diamond Blade for Grooving Machine

-

NTBM Series Medium Speed VFFS Machine

NTBM Series Medium Speed VFFS Machine

-

Airport Runway Diamond Blade

Airport Runway Diamond Blade

-

DCS10F Weigh Filler for Powder

DCS10F Weigh Filler for Powder

-

Chisel

Chisel

-

Baby Diaper - Super Absorption

Baby Diaper - Super Absorption