DCS5Q-2 High Speed Weigh Filler for Granule

Front view

Rear view

Left side view

Right side view

Top view

The DCS5Q-2 high speed weigh filler for granule, compared with DCS1-2 model, comes with higher scale placement. This is because we adopt four stout metal supports to hold the entire filling equipment for enlarged ground clearance. As a result, there is sufficient space for connection with other equipment to form comprehensive weighing and packing line.

Our high speed weigh filler is cut out for packaging granules in industries of food, feedstuff, seeds and chemical, including rice, corn, wheat, soybean, gourmet powder and granulated sugar, as well as all kinds of vitamins, amino acids and urea.

Advantage

1. Latest technology

Feeding method of this is semi-automatic packaging system is the advanced combination of gravity and vibration, whereby ensuring feeding speed and accuracy.

2. Low noise production

Unique door opening unit minimizes the impact and shock of door movements, resulting in drastically reduced noise production.

3. Well-conceived structure

Compacted and optimal layout brings along space efficiency and stylish appearance.

4. Easy operation

User friendly idea has been pored into the design of our high speed weigh filler, thus ensuring comfortable placement of electronic control unit with ease of operation.

Specification

| Filling range | 0.5 to 10kg |

| Production rate | 800 to 1500 bags/h |

| Filling accuracy | × (0.2) level |

| Main part dimension | 1100 × 760 × 2535mm |

| Main motor power | 600W |

| Feeding size | Φ150mm |

| Working environment | -20℃ to 40℃, relative humidity ≤ 90% |

| Power supply | 380±10%, 220±10%, 50Hz |

| Air supply pressure | 0.8MPa |

Links:https://globefindpro.com/products/75901.html

-

Stop Pin

Stop Pin

-

DCS50PD Weigh Filler

DCS50PD Weigh Filler

-

DCS1-2 High Speed Weigh Filler for Granule

DCS1-2 High Speed Weigh Filler for Granule

-

Piston

Piston

-

Marine Sound Reduction Door

Marine Sound Reduction Door

-

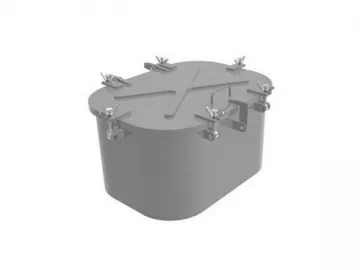

Weathertight Hatch Cover

Weathertight Hatch Cover

-

DCS50HFP Weigh Filler for Powder

DCS50HFP Weigh Filler for Powder

-

DCS0.05 Weigh Filler for Granule

DCS0.05 Weigh Filler for Granule

-

Chisel Pin

Chisel Pin

-

NTBL Series VFFS Machine for Large Pouch

NTBL Series VFFS Machine for Large Pouch

-

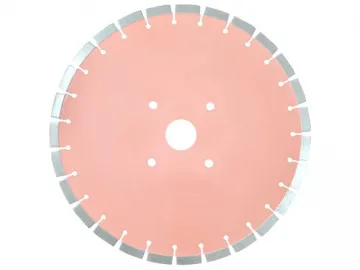

Sandstone Diamond Blade

Sandstone Diamond Blade

-

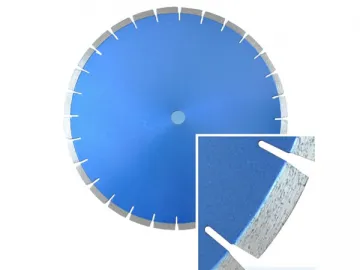

Green Concrete Diamond Blade

Green Concrete Diamond Blade