Rockwool Insulation

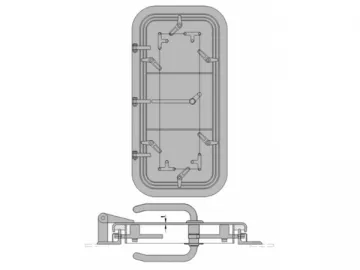

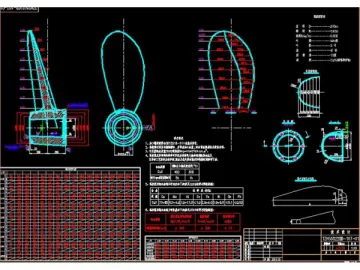

The main raw material for making rockwool insulation is basalt. After melting at a high temperature container such as cupola or other kilns, the basalt is processed by the high-speed centrifugal equipment to be inorganic fibers. Finally, it is finished by different forming processes upon customers' requirements. With the features of thermal insulation, heat preservation, sound absorption, and chemical corrosion resistance, the rock wool is widely used in the insulation system of bulkheads and decks that need fireproof partitions. According to the requirements of ship types, fire class, and applications, we will provide bespoke insulation solutions to you.

Our marine insulation is in conformity with the amended SOLAS and has passed the tests of different classes of fireproof partitions for decks and bulkheads. In addition, it is approved by Classification Society such as CSS, ABS, and DNV. The marine rock wool insulation has been rated by CB/T3830-1998.

Specifications

| Noninflammability | In line with IMO.FTPC Part1/IMO.A799(19) |

| Fire Class | A60, A30, B15 |

| Unit Weight | 60-150 (kg/m3) |

| Common Thickness | 25, 30, 50, etc. (mm) |

| Common Length | 1000mm |

| Coating Layer | Fiberglass cloth or aluminum foil cloth |

| Mounting Methods | High temperature resistant adhesive and marine rivets (12-16 sets per square meter) |

Links:https://globefindpro.com/products/75927.html