Acrylic Foam Tape

The acrylic foam tape has become an indispensable product with the growing social diversity and progress of science and technology. Now being widely promoted in automotive, electronic, plastic, and metal industries, the acrylic foam tape occupies an important position in adhesive tape industry.

We offer all-acrylic-backed foam tape covered with release film or release paper. It insulates the protected objects from water, shock, heat, noise and so on. This tape is easy for die-cutting and easy to stick to challenging surfaces, such as rubber, metal, wood, paper and silicone. Under both high and low temperatures, it shows good endurance and excellent adhesion on both high and low surface energy materials. It is also capable of resisting chemical solvents, moisture, and UV.

Our acrylic foam tape is available in gray, black, white, and grayish clear. The thicknesses include 0.4mm, 0.5mm, 0.8mm, 1.0mm,1.2mm and 2.0mm as options. Customized thickness is also available.

Why Us

1. 21 years of export experience, especially good credibility in Japan and Europe

2. Manufacturer’s certification by third party, OEM available.

3. Approved by SGS environmental inspection.

4. Best prices, tailored sizes available.

5. 15 to 30 days’ fast delivery.

6. Located in China’s largest port city-Shanghai.

7. Quick response to all inquiries within 24 hours.

Applications

1. The acrylic foam tape can provide superior adhesive force and dust prevention in glass curtain wall assembly; satisfy a variety of needs in building construction,such as insulation, sealing, connection, bundling, repair, marking and so on.

2. For fixing in the processing and assembly of digital products, home appliances, billboards, electronic signs, LED panels, etc.

3. As auto foam tape: for the adhesive fixing of car rub rail, bumper, bumper plate, nameplate, pedal, interior and exterior decoration, as well as motorcycle nameplate, tag, and caption.

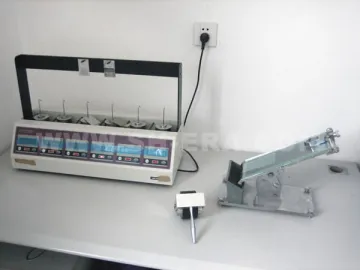

| Item | Adhesive | Backing | Color | Thickness (mm) | Release liner | Tensile strength to aluminum room temperature (gf/cm^2) | Peel adhesion to stainless steel room temperature (gf/25mm) | Holding power to stainless steel 80° temperature 1000g staiticload (hr) | (Holding force) to stainless steel room temperature after 20mins (gf/cm^2) | (Holding force) to stainless steel room temperature after 24hours (gf/cm^2) | (Temperature tolerance) short term 4hours conditioning arindicated temperature with 100g static load (℃) | (Temperature tolerance) long time maximum temperature where tape supports 250g in static shear for 10000 minutes (℃) |

| Acrylic Foam Tape | Acrylic | Acrylic foam | Grey | 0.4mm±50mic | Red pe | ≥7500 | ≥3300 | >24 | ≥4500 | ≥7000 | 160 | 100 |

| Acrylic | Acrylic foam | White | 0.4mm±50mic | Red pe | ≥8200 | ≥3400 | >24 | ≥5200 | ≥7800 | 160 | 100 | |

| Acrylic | Acrylic foam | Grey | 0.5mm±50mic | Red pe | ≥8400 | ≥2100 | >24 | ≥4500 | ≥7900 | 160 | 100 | |

| Acrylic | Acrylic foam | White | 0.5mm±50mic | Red pe | ≥8400 | ≥2100 | >24 | ≥4500 | ≥7900 | 160 | 100 | |

| Acrylic | Acrylic foam | Grey | 0.8mm±50mic | Red pe | ≥6500 | ≥3700 | >24 | ≥3700 | ≥6500 | 160 | 100 | |

| Acrylic | Acrylic foam | Grey | 0.8mm±50mic | Red pe | ≥6500 | ≥3700 | >24 | ≥3700 | ≥6500 | 160 | 100 | |

| Acrylic | Acrylic foam | Clear | 1.0mm±50mic | Red pe | ≥6000 | ≥3400 | >24 | ≥3000 | ≥4500 | 160 | 100 | |

| Acrylic | Acrylic foam | Grey | 1.2mm±50mic | Red pe | ≥6000 | ≥3900 | >24 | ≥3500 | ≥6000 | 160 | 100 | |

| Acrylic | Acrylic foam | White | 1.2mm±50mic | Red pe | ≥8400 | ≥1900 | >24 | ≥4500 | ≥7400 | 160 | 100 | |

| Acrylic | Acrylic foam | Grey | 1.5mm±50mic | Red pe | ≥5500 | ≥3900 | >24 | ≥3200 | ≥5500 | 160 | 100 | |

Links:https://globefindpro.com/products/76197.html