ZQ Series Drill Pipe Tong

Overview

The ZQ series drill pipe tong is widely used for mining and drilling operation. It is engineered with open-throat head which can freely come away from drill pipe, improving maneuverability of the entire power tong. Meanwhile, quick and safe make-up and break-out of drill pipe and drill collars are available without needing cathead, rig tong or spinning chain.

Combining spinning and torque wrenches in a modular design for easy maintenance and service, this well drilling tool was born in 1973, the design of which was finalized in 1980 after continuous improvement. In virtue of mature technical performance, unique design, delicate processing as well as high speed and safety, this drill pipe tong has been applied to multiple national petroleum drilling projects, and highly praised by industry insiders. It is especially suited to projects requiring frequent and long-term drilling operation.

Technical Features

1. As all units are powered by compressed air except hydraulic motor, hydraulic system is largely simplified.

2. The drill pipe power tong comes with integrated upper and lower tongs to avoid dill pipe crooking caused by large torque as well as to prevent drill pipe from slip.

3. To simplify hoisting operation, our drill pipe tong adopts floating tong head design. Generally, a pulley is mounted onto derrick, and one end of steel wire rope is fastened to the power tong, and the other end of steel wire rope is secured to chain block for height adjustment.

4. Automatic self-centering clamping mechanism sound ensures reliably secured joints.

5. Air cylinder is used for oilfield equipment shifting, thus saving manpower.

6. Return to breakout gap is extremely convenient, and conversion between makeup and breakout is fast and reliable.

7. Torque and speed of our drill pipe tong are controllable, and maximum torque and speed can be realized both in positive and negative directions.

8. Brake band and clamping cylinder are adopted for clamping.

9. For large torque of 75-100kN·m, doorframe can be used to avoid head of drill pipe tong from deformation.

10. Our drill pipe tong supports both electrical drive and belt drive.

| No. | Item | Code name | Quantity |

| 1 | Doorframe | 01.02.02.00M | 1 |

| 2 | Tong head | 01.01.00M | 1 |

| 3 | Suspender | 01.09.00B | 1 |

| 4 | Control assembly | 01.08.00M | 1 |

| 5 | Oil motor | JML12-F0.8H | 1 |

| 6 | Planetary transmission | 01.03.00M | 1 |

| 7 | Shifting cylinder | 02.00M | 1 |

| 8 | Clamping cylinder | 01.04.00M | 1 |

Technical Parameters

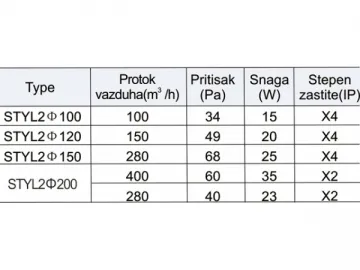

| Model | ZQ127-25 | ZQ162-50 | ZQ203-100 | ZQ203-125 | ||

| Size range | Drill pipe | mm | 65-127 | 85-162 | 127-203 | 127-203 |

| inch | 23/8-31/2 | 23/8-5 | 31/2-8 | 31/2-8 | ||

| Casing | mm | 65-127 | 114.3-153.7 | |||

| inch | 23/8-31/2 | 41/2-51/2 | ||||

| Oil pipe | mm | 65-127 | 138-156 | |||

| inch | 23/8-31/2 | 31/2-41/2 | ||||

| Max. torque | kN·m | 25 | 50 | 100 | 125 | |

| ft·lbf | 18440 | 36880 | 73750 | 92200 | ||

| Speed (High gear) | rpm | 65 | 60 | 40 | 40 | |

| Speed (Low gear) | rpm | 10.5 | 4.1 | 2.7 | 2.7 | |

| Air pressure | MPa | 0.5-0.9 | ||||

| psi | 72-130 | |||||

| Pressure rating | MPa | 12 | 14 | 16.6 | 20.7 | |

| psi | 1740 | 2030 | 2400 | 3000 | ||

| Flow rating | L/min. | 120 | 120 | 114 | 114 | |

| gpm | 31.7 | 31.7 | 30 | 30 | ||

| Shifting distance | mm | 1000 | 1000 | 1500 | 1500 | |

| inch | 39.4 | 39.4 | 59 | 59 | ||

| Overall dimension | mm | 1110×735×815 | 1570×800×1190 | 1760×1000×1360 | 1760×1080×1360 | |

| inch | 44×31×32 | 62×31×47 | 69×39×53 | 69×40.5×53 | ||

| Weight | kg | 620 | 1500 | 2400 | 2650 | |

| lb | 1360 | 3310 | 5290 | 5840 | ||

Links:https://globefindpro.com/products/78010.html