DIN 1629 Special Seamless Steel Tube

The special seamless steel tube reaches DIN 1629 standard. This alloy steel tubing contains a large number of other chemical elements, which helps to improve mechanical property. Usually, adding less than 5% elements may increase strength and hardenability, and adding more than 5% elements can create special properties, like corrosion resistance and extreme temperature stability.

To meet the requirements for excellent quality, the industrial pipe is made of ST37.0, ST44.0 or ST52.0 steel. The seamless steel tube is extensively applied in the manufacture of pipeline, vessel, equipment, pipe fitting and so on.

Parameters

1. Standard: DIN 1629

2. Steel grade: ST37.0, ST44.0, ST52.0

3. Delivery condition: Hot rolling

4. Outer diameter: 70MM-610MM

5. Wall thickness: 6MM-35MM

6. Tolerance: DIN 1629 standard

7. Length: Customization

8. Certificate: EN 10204/3.1

Delivery Condition

| Steel grade | Delivery condition |

| ST37 | Hot rolling |

| ST44 | Hot rolling |

| ST52 | Hot rolling |

Chemical Composition (Heat Analysis)%

| Steel grade | C | Si | Mn | P | S |

| Max. | Max. | Max. | |||

| ST37 | 0.17 | - - | - - | 0.040 | 0.040 |

| ST44 | 0.21 | - - | - - | 0.040 | 0.040 |

| ST52 | 0.22 | - - | - - | 0.040 | 0.035 |

Mechanical Property of Seamless Steel Tube

| Steel grade | Min. yield strength (Mpa) | Tensile strength (Mpa) | Elongation | |

| Min. % | ||||

| T(mm) | I | |||

| ≤16 | >16 | |||

| ≤40 | ||||

| ST37 | 235 | 225 | 350-480 | 25 |

| ST44 | 275 | 265 | 420-550 | 21 |

| ST52 | 355 | 345 | 500-650 | 21 |

Links:https://globefindpro.com/products/78922.html

-

Captopril

Captopril

-

Nicotinamide

Nicotinamide

-

Clindamycin Phosphate

Clindamycin Phosphate

-

Metformin HCL

Metformin HCL

-

API 5CT Oilfield Casing and Tubing

API 5CT Oilfield Casing and Tubing

-

Nilestriol

Nilestriol

-

Gliclazide

Gliclazide

-

Echinacea Herb Extract

Echinacea Herb Extract

-

ASME SA213/ASTM A213 Seamless Steel Pipe for Boiler, Superheater and Heat-Exchanger

ASME SA213/ASTM A213 Seamless Steel Pipe for Boiler, Superheater and Heat-Exchanger

-

EN 10216 Seamless Steel Tube for Normal Temperature

EN 10216 Seamless Steel Tube for Normal Temperature

-

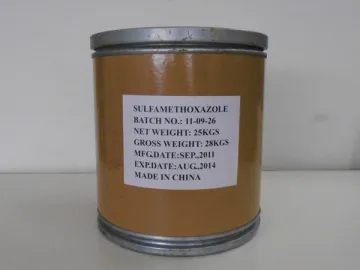

Sulfamethoxazole

Sulfamethoxazole

-

Radish Red Pigment

Radish Red Pigment