Microwave Pharmaceutical Dryer

Introduction

In the pharmaceutical production, raw materials are usually processed into particles with an aim to guarantee the uniformity and mobility of medicines. Included examples are pills, capsules, and tablets.

The microwave pharmaceutical dryer implements low temperature drying and sterilization via the utilization of microwave thermal and non-thermal effects. Microwave energy is directly radiated to drugs, leading to the internal temperature rising and pressure formation in drugs. The internal pressure generated speeds up the vaporization inside drugs. A proper amount of hot air will pass through the microwave drying equipment for taking away the evaporated moisture. Temperature, humidity, and amount of hot air should be strictly controlled for making sure high quality drugs.

Advantages

Traditionally, hot air or far infrared ray is used for pharmaceutical drying, while sterilization is finished through the methods including high temperature and high pressure as well as cobalt-60 irradiation. All those traditional drying methods are low in the utilization rate of thermal efficiency, long in heating time, and large in floor coverage. No evidence shows that they are beneficial for environment protection. In addition, sterilization needs pressurizing, and requires 20 to 40 minutes of heat preservation under the high temperature of 120℃. By then, drug efficacy and nutrition ingredients will be damaged to a certain degree.

Our microwave pharmaceutical dryer is specially designed to get rid of the drawbacks of traditional heating methods. Compared to the aforesaid traditional methods, it holds the advantages as below:

1. The drug dryer uses microwave to speedily, uniformly heat drugs in a short time. For instance, hot air drying requires 20 hours to dry drugs with water content of 80% to be with 20% water content. However, microwave drying only needs 2 hours to finish the drying process.

2. It has sterilization function. Microwave treated pills has the quantity of bacteria decreased by 78% - 99%, compared to the untreated ones. They contain 15% - 90% less bacteria amount than those treated by drying rooms. In general, low temperature sterilization time ranges from 10 seconds to several minutes. And microwave drying temperature is usually below 80℃, which seldom affects the main ingredients of drugs. In conclusion, the microwave pharmaceutical dryer ensures the drug efficacy.

3. Our microwave dryer features selective heating and low temperature drying, so it makes clean drugs of superior quality. Drugs after microwave drying, are uniform in water content, free from wrinkled or cracked surfaces.

Application

The microwave pharmaceutical dryer is ideally suited to the drying, dehydration, disinfection, sterilization, and mildew proof treatment of all sorts of medicines and drugs. It is chiefly used to the drying and sterilization of pills, tablets, powder medicine, drug particles, oral liquid, or others. Microwave treated pharmaceutical is convenient in storage.

Our equipment comes with many varieties, e.g. pills dryer, tablets drying and sterilization equipment, powdery medicine dryer, and so on.

Links:https://globefindpro.com/products/78996.html

-

Venere Polished Porcelain Tiles

Venere Polished Porcelain Tiles

-

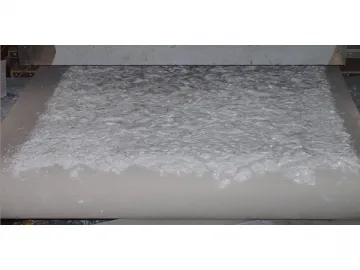

Microwave Chemical Material Dryer

Microwave Chemical Material Dryer

-

Brati Polished Porcelain Tiles

Brati Polished Porcelain Tiles

-

Linen Glazed Porcelain Tiles

Linen Glazed Porcelain Tiles

-

Mosaic Tiles

Mosaic Tiles

-

Super White Body Polished and Glazed Porcelain Tile

Super White Body Polished and Glazed Porcelain Tile

-

Wood Effect Glazed Porcelain Tiles

Wood Effect Glazed Porcelain Tiles

-

Saturno Polished Porcelain Tiles

Saturno Polished Porcelain Tiles

-

Rainbow Polished Porcelain Tiles

Rainbow Polished Porcelain Tiles

-

Microwave Meat Tempering System

Microwave Meat Tempering System

-

Solid Color Glazed Porcelain Tiles

Solid Color Glazed Porcelain Tiles

-

Microwave Dental Ceramic Sintering Furnace

Microwave Dental Ceramic Sintering Furnace