QT6-15A Fully Automatic Concrete Block Production Line

The QT6-15A concrete block production line realizes fully automatic operation, which helps to cut manpower. With high compactness, its finished blocks allow stacking immediately after molding. Therefore, the standard brick production line needs fewer pallets than many like products. Due to the super steel rack and imported electro-hydraulic components, it is proud of stable operation, low failure rate, less maintenance, good durability and high productivity. Its output reaches up to 16360 pieces every 8 hours and its molding cycle is only 15 seconds.

Features

1. The concrete block production line makes use of the vibrating case driven by a hydraulic motor, which effectively increases vibration frequency. The motor adopts the on time start-stop system, so as to improve its utilization efficiency and reduce the consumption of dynamic potential energy.

2. With the help of PLC, it allows for computer operation, random signal analysis, fault diagnosis and material parameter setting.

3. Different from traditional brick moulding machines, our machine is provided with a storage hopper and a feed hopper. Materials will be supplied in a fixed quantity, so as to avoid concrete solidifying in advance and minimize charging time. To decrease labor force and production area, the production line is equipped with an automatic stacker.

4. Its feeding device is designed to pour materials into a molding flask rapidly and uniformly, so as to dramatically reduce the weight error of produced blocks.

Parameters

| Productive capacity | 400x200x200mm: 11500 PCS /8hour 400x150x200mm: 15300 PCS/8hour 400x100x200mm: 16360 PCS/8hour |

| Power | 36.4 kw |

| Overall size | 3800X2000X2510mm |

| Cycle | 15s |

| Pallet size | 900x550x30mm |

| Vibration force | 88KN |

| Vibration frequency | 4000-4800/Minute |

| Nominal pressure | 21Mpa |

| Total weight | 7000kg |

| Power source | 380v/50HZ |

Links:https://globefindpro.com/products/80566.html

-

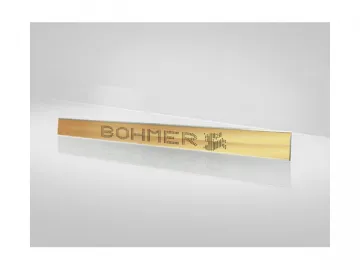

Centre Bevel Cutting Rules

Centre Bevel Cutting Rules

-

Label Perforating Rules

Label Perforating Rules

-

SY1-20 Hydraulic Interlocking Brick Making Machine

SY1-20 Hydraulic Interlocking Brick Making Machine

-

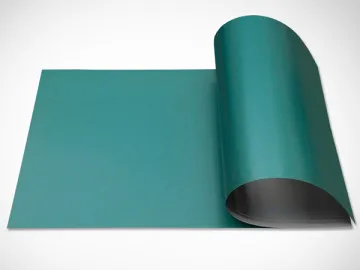

CTCP Plate

CTCP Plate

-

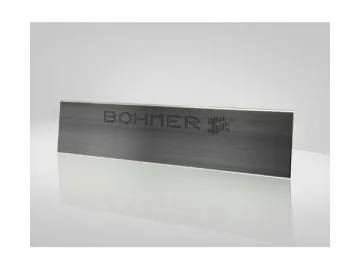

Long Centre Bevel Cutting Rules

Long Centre Bevel Cutting Rules

-

Special Label Rules

Special Label Rules

-

Special Steel Cutting Rules

Special Steel Cutting Rules

-

PLD800 Two-Hopper Concrete Batching Plant

PLD800 Two-Hopper Concrete Batching Plant

-

SY1-25 Hydraulic Interlocking Brick Making Machine

SY1-25 Hydraulic Interlocking Brick Making Machine

-

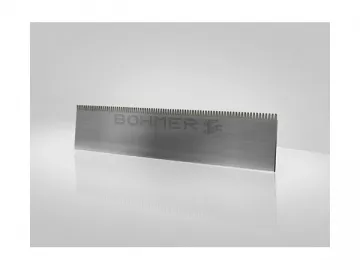

Sharp Teeth Rules

Sharp Teeth Rules

-

Side Ejection Punch

Side Ejection Punch

-

QTJ4-40 Block Making Machine

QTJ4-40 Block Making Machine