QC11Y/K Hydraulic Guillotine Shearing Machine

Features

1. The QC11Y/K hydraulic guillotine shearing machine is entirely welded and treated with fireplace tempering.

2. It adopts the hydraulic gearing and the energy accumulator for return stroke.

3. The rolling guide with three-point support facilitates to improve the cutting quality.

4. The rectangular blade comes with 4 usable blade angles and has a long service life.

5. The adjustment of blade angles complies with the indicator, fast and convenient.

6. A beam alignment device is configured, which also can adjust the stroke of upper tool post in stepless mode.

7. The fence-type safety protection device is adopted by the QC11Y/K hydraulic guillotine shearing machine.

8. The back gauge dimension and cutting times are available in digital display.

9. The cutting angle is adjustable.

10. The QC11Y adopts Estun E10 system.

11. The QC11K-NC series is equipped with Estun E200 control system.

12. The QC11K-CNC series is applicable for plate cutting due to its adoption of DELEM DAC310/DAC360 CNC control system by Netherlands. Its back gauge adopts imported ball screw and liner guideway

Technical Parameters of QC11Y/QC11K Series

| Item | Workable plate thickness (mm) | Workable plate width (mm) | Stroke (mm) | Back gauge stroke (mm) | Cutting angle | Back gauge range (mm) | Motor power (KW) |

| 6×2500 | 6 | 2500 | 16-35 | 20-600 | 30'-1°30 | 600 | 7.5 |

| 6×3200 | 6 | 3200 | 14-35 | 20-600 | 30'-1°30 | 600 | 7.5 |

| 6×4000 | 6 | 4000 | 10-30 | 20-600 | 30'-1°30 | 600 | 7.5 |

| 6×5000 | 6 | 5000 | 10-30 | 20-800 | 30'-1°30 | 800 | 11 |

| 6×6000 | 6 | 6000 | 8-25 | 20-800 | 30'-1°30 | 800 | 11 |

| 8×2500 | 8 | 2500 | 14-30 | 20-600 | 30'-1°30 | 600 | 11 |

| 8×3200 | 8 | 3200 | 12-30 | 20-600 | 30'-2° | 600 | 11 |

| 8×4000 | 8 | 4000 | 10-25 | 20-600 | 30'-2° | 600 | 11 |

| 8×5000 | 8 | 5000 | 10-25 | 20-800 | 30'-2° | 800 | 15 |

| 8×6000 | 8 | 6000 | 8-20 | 20-800 | 30'-2° | 800 | 15 |

| 12×2500 | 12 | 2500 | 12-25 | 20-800 | 30'-2° | 800 | 15 |

| 12×3200 | 12 | 3200 | 12-25 | 20-800 | 30'-2° | 800 | 15 |

| 12×4000 | 12 | 4000 | 8-20 | 20-800 | 30'-2° | 800 | 15 |

| 12×5000 | 12 | 5000 | 8-20 | 20-800 | 30'-2° | 800 | 22 |

| 12×6000 | 12 | 6000 | 6-20 | 20-1000 | 30'-2° | 1000 | 30 |

| 16×2500 | 12 | 2500 | 12-20 | 20-800 | 30'-1°30 | 800 | 22 |

| 16×3200 | 16 | 3200 | 12-20 | 20-800 | 30'-1°30 | 800 | 22 |

| 16×4000 | 16 | 4000 | 8-15 | 20-800 | 30'-1°30 | 800 | 22 |

| 16×5000 | 16 | 5000 | 8-15 | 20-1000 | 30'-1°30 | 1000 | 30 |

| 16×6000 | 16 | 6000 | 6-15 | 20-1000 | 30'-1°30 | 1000 | 37 |

| 20×2500 | 20 | 2500 | 10-20 | 20-800 | 30'-3° | 800 | 30 |

| 20×3200 | 20 | 3200 | 10-20 | 20-800 | 30'-3° | 800 | 30 |

| 20×4000 | 20 | 4000 | 8-15 | 20-800 | 30'-3° | 1000 | 30 |

| 20×5000 | 20 | 5000 | 8-15 | 20-1000 | 30'-3° | 1000 | 37 |

| 20×6000 | 20 | 6000 | 6-15 | 20-1000 | 30'-3° | 1000 | 37 |

| 25×2500 | 25 | 2500 | 8-15 | 20-800 | 30'-3° | 800 | 37 |

| 25×3200 | 25 | 3200 | 8-15 | 20-800 | 30'-3° | 800 | 37 |

| 25×4000 | 25 | 4000 | 6-12 | 20-1000 | 30'-3° | 1000 | 37 |

| 32×2500 | 32 | 2500 | 6-12 | 20-1000 | 30'-4° | 1000 | 45 |

| 32×3200 | 32 | 3200 | 8-12 | 20-1000 | 30'-4° | 1000 | 55 |

| 40×2500 | 40 | 2500 | 4-10 | 20-1000 | 30'-4° | 1200 | 55 |

| 40×3200 | 40 | 3200 | 4-10 | 20-1000 | 30'-4° | 1200 | 55 |

Related Names

Metal Cutting Guillotine | Guillotine Metal Cutter | Mechanical Shear Equipment

Links:https://globefindpro.com/products/81244.html

-

Low Voltage T5 LED Tube (DC12/24V)

Low Voltage T5 LED Tube (DC12/24V)

-

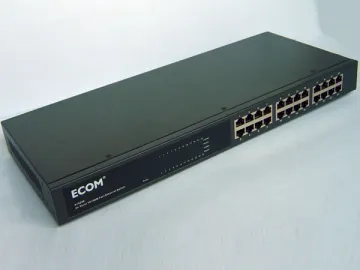

24-Port 10/100M and 2-Port Gigabit Unmanaged Switch with 2 Combo SFP Slots

24-Port 10/100M and 2-Port Gigabit Unmanaged Switch with 2 Combo SFP Slots

-

Energy Saving 16-Port 10/100M Unmanaged Switch

Energy Saving 16-Port 10/100M Unmanaged Switch

-

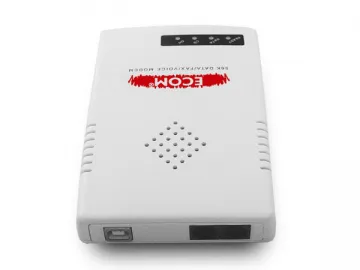

External RS232 56K Modems

External RS232 56K Modems

-

Classroom Chair

Classroom Chair

-

Kids' Adjustable Table

Kids' Adjustable Table

-

Energy Saving 24-Port 10/100M Unmanaged Switch

Energy Saving 24-Port 10/100M Unmanaged Switch

-

8/10/16/24-Port 10/100M Smart Switches

8/10/16/24-Port 10/100M Smart Switches

-

16/24-Port Gigabit Managed Switches

16/24-Port Gigabit Managed Switches

-

External 56K USB Modems

External 56K USB Modems

-

Unmanaged Switch with 24 Gigabit Ports and 2 SFP Slots

Unmanaged Switch with 24 Gigabit Ports and 2 SFP Slots

-

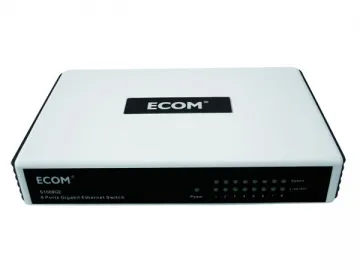

Energy Saving 10/100/1000M Unmanaged Switches

Energy Saving 10/100/1000M Unmanaged Switches