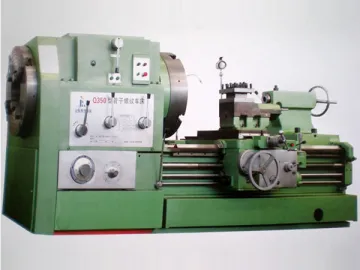

Q350 Pipe Threading Lathe Machine

Features

1. Due to the supersonic frequency hardening for the machine bed slide way and the inlaid wear-resisting material structure for the saddle slide way, both the slide ways of the Q350 pipe threading lathe machine are provided with high durability and wear resistance.

2. The product utilizes the floor type body design with good overall rigidity. It can carry out heavy cutting to the high strength materials.

3. The spindle of the machine has large diameter bore. It is outfitted with the front and rear double chucks. As a result, the labor intensity of the operators can be alleviated, and the working efficiency can be enhanced as well.

4. The pipe threading lathe machine avails itself of the hydraulic control to implement spindle brake as well as rotation direction changing. The brake effect is sensitive and reliable.

5. The headstock uses the hydraulic oil forced lubricating, which is beneficial to the heat dissipation.

6. The CNC operating system can be selected as requested.

Application Range

As the special machine tool for processing various kinds of pipes and pipe threads in the fields of oil drilling, geology and metallurgy, the pipe threading lathe machine can not only lathe the pipe thread, but also process the metric and inch threads of circular cylinder and taper tube. It can also be taken as the ordinary machine tool for processing outer circle, hole boring as well as inside and outside conical holes. The machine is professional in processing and repairing the pipes and fittings.

Manufacturing Equipment

The involved manufacturing equipment for the product has slideway grinding machine, gantry planing machine, gantry milling machine, CNC boring machine tool, supersonic frequency induction hardening machine, etc.

| Overall Dimension and Weight | ||

| Length | 3550mm | |

| Width | 1900mm | |

| Height | 1630mm | |

| Total Weight (excluding support stand) | 8200kg | |

| Main Specification | ||

| Max. Machining Taper | 1: 4 | |

| Max. Work Piece Rotation Diameter | 1000mm | |

| Processing Pipe Diameter | 114-350mm | |

| Max. Machining Length of Ordinary Shaft | 1000-6000mm | |

| Max. Stroke of Taper Bar | 930mm | |

| Spindle | ||

| Number of Spindle Forward Speeds | 9 | |

| Number of Spindle Reverse Speeds | 3 | |

| Forward Speed Range | 6.6-198r/min | |

| Reverse Speed Range | 13.5-200.9r/min | |

| Spindle Bore Diameter | 350mm | |

| Feeding Parameter | ||

| Number of Longitudinal and Cross Feed Rates | 32 for Each | |

| Toolpost Feeding Range per Revolution of Spindle | Longitudinal: 0.1-1.44mmTransverse: 0.04-0.72mm | |

| Number of Machinable Metric Thread | 24 | |

| Number of Machinable Inch Thread | 24 | |

| Machinable Metric Thread Pitch | 1-15mm | |

| Machinable Inch Thread Pitch | 1-15t.p.i | |

| Saddle Longitudinal Rapid Traverse Speed | 4m/min | |

| Longitudinal Travel of Saddle When Apron Handwheel Rotating One Grid | 1mm | |

| Toolpost Travel When Compound Rest Dial Turning A Grid | 0.05 | |

| Toolpost Travel When Bottom Slide Dial Turning A Grid | 0.05mm | |

| Vertical Distance from Spindle Center Line to Toolpost Installation Benchmark | 33mm | |

| Tailstock | ||

| Center Barrel Diameter | 100mm | |

| Center Barrel Stroke | 250mm | |

| Center Barrel Taper | Morse No. 6 | |

| Center Taper | Morse No. 6 | |

| Tailstock Transverse Movement Range | ±15mm | |

| Power | ||

| Main Electric Motor | Y180M-4 18.5kW 1470r/min 380V | |

| Main Motor Belt | B1727 | |

| Fast Electric Motor | NY80-4 1.1kW 1350r/min 380V | |

| Clamping Motor | YXZ90-L-4 1.5kW 1400r/min 380V | |

| Gear Pump | CB-B6 2.5Mpa 1450r/min | |

Related Names

Pipe Machining Tool | Hydraulic Control Lathe | Thread Grinding Tool

Links:https://globefindpro.com/products/81253.html

-

Kids' Square Table

Kids' Square Table

-

Single Classroom Desk and Chair

Single Classroom Desk and Chair

-

Wire Desk Tray

Wire Desk Tray

-

HY-0533 & HY-0534 Laboratory Chair

HY-0533 & HY-0534 Laboratory Chair

-

Wooden Kids' Chair

Wooden Kids' Chair

-

XYX-3 Trailer-Mounted Water Well Drilling Rig

XYX-3 Trailer-Mounted Water Well Drilling Rig

-

Teacher Chair

Teacher Chair

-

Chair Seat and Back

Chair Seat and Back

-

Kids' Adjustable Table

Kids' Adjustable Table

-

Classroom Chair

Classroom Chair

-

External RS232 56K Modems

External RS232 56K Modems

-

Energy Saving 16-Port 10/100M Unmanaged Switch

Energy Saving 16-Port 10/100M Unmanaged Switch