XY-8 Core Drilling Rig

The XY-8 core drilling rig has large drilling capacity. It is developed by fully considering the needs of the users in geological prospecting field, and assimilating the advantages and characteristics of all kinds of the similar products in domestic and foreign markets.

The product is highly configured with the pneumatic shift automobile gearbox, centralized lubrication cooling mechanism, and involute spline gyrator. It is widely applied into the fields such as geology, metallurgy, coal, hydrology, water well, engineering, etc. The machine can be taken for alloy and diamond core drilling with large and small drilling diameter. It is also suitable for metal and non-metal solid mineral exploration, shallow oil and natural gas exploration, geothermal well exploration, mine tunnel ventilation and water draining, large diameter pile foundation engineering construction, etc.

Main Features

1. The core drilling rig is matched with pneumatic shifting Fast 8JS118 auto transmission and clutch, allowing for compact and reasonable structure, smooth operation, stable performance, and universal property.

2. It adopts the car-level flexible shaft gear shift mechanism to realize remote control of gearbox shift. The operation of pneumatic gear shift is handy and flexible with high user-friendly degree.

3. The core drilling rig is fitted with reasonable speed range. It has 8 forward gears and 1 reverse gear. The torque at low speed is as large as 8000N.m.

4. The product uses the centralized forced lubrication mechanism. As long as the equipment operates, the independent lubricating oil pump would start to pump the lubricating oil. Then, the lubricating oil arrives at each part needing lubrication via the grease separator. At the same time of lubricating the transmission mechanism, it would bring away the heat to avoid overheat of the parts under the conditions of high speed and high load (the lubricating system is configured with the independent condenser).

5. The core drilling rig employs the involute spline spindle instead of the traditional hexagon spindle, enabling doubled and redoubled transmission efficiency and bearing capacity of the gyrator. Meanwhile, the spindle has large bore diameter of 96mm. Together with double cylinders hydraulic feeding, long stroke of up to 1000mm, and strong technological adaptability, it goes especially well with the large diameter drilling rod wireline coring (upper part coring) drilling, and contributes largely to the improvement of drilling efficiency and the reduction of drilling accident in the hole.

6. Fabricated with large drilling capacity, the machine can attain the rated drilling depth of 1650m with 71mm wireline coring drilling rod.

7. Featuring good dismountability, it is light with the net weight of 6500kg.

8. The hydraulic loosening normally closed hydraulic chuck that the core drilling rig adopts has novel structure and good compensatory. Fabricated with the structure of cemented carbide embedded with welded slip, it has large chucking power, long service lifetime and stable performance.

9. The product is configured with the hydromatic brake. In the case of deep well drilling, the process of running the drilling tool into the hole is smooth and safe.

10. Using gear pump for oil supply enables low power consumption, low oil temperature of the hydraulic system, and stable operation. The operating system of the product is mounted with the hand-operated oil pump for dealing with the case of the power machine failing to work. In that case, the hand-operated oil pump can play a role to pull the drilling tools out of the bottom of the hole for avoiding the drill burying accident.

11. The core drilling rig is provided with advanced and compact structure, as well as reasonable layout. All its parts are exposed to the outside with no overlapping, making the maintenance, servicing and repair easy to carry out.

12. The product has low center of gravity and long backward travel of 530mm. Being fixed easily and firmly, it performs excellently in high speed drilling stability.

13. The shockproof instrument is also available for facilitating mastering the conditions in the hole. The control handles of the machine are not too many. They are arranged reasonably for enabling flexible and reliable operation.

Technical Parameters

1. Drilling Capacity

| Type of Drilling Rod | Specification of Drilling Rod | Drilling Depth | |

| Domestic Drilling Rod | Φ50×4.75 | 2200m | |

| Φ50×5 | 2000m | ||

| Φ60×6 | 1450m | ||

| Φ71×5 | 1650m | ||

| Φ73×7 | 1000m | ||

| Φ89×5 | 1300m | ||

| Φ89×10 | 600m | ||

| DCDMA (Diamond Core Drilling Manufacturers Association) Drilling Rod | Internally Upset Drilling Rod | BW | 2200m |

| NW | 1700m | ||

| HW | 1150m | ||

| Wireline Coring Drilling Rod | BQ | 2200m | |

| NQ | 1700m | ||

| HQ | 1150m | ||

| PQ | 800m | ||

| BCQ | 2500m | ||

| NCQ | 2000m | ||

| HCQ | 1550m | ||

2. Gyration Angle of Gyrator: 0°-360°

3. Power Machine

| Type | Model | Power | Speed |

| Electric Motor | Y280S-4 | 75kW | 1480rpm |

| Diesel Engine | Yuchai YC6A240-33 | 177kW | 2300rpm |

4. Gyrator

A. Type: Double Hydraulic Cylinders Hydraulic Feeding Mechanical Gyration Type

B. Drilling Angle: 90°-65°

C. Spindle Bore Diameter: 96mm

D. Spindle Speed

a. Power Machine Being Electric Motor with the Speed of 1480rpm

Forward Speed: 74, 106, 150, 208, 300, 431, 609, 845rpm

Reverse Speed: 74rpm

b. Power Machine Being Diesel Engine with the Speed of 2300rpm

Forward Speed: 110, 157, 222, 309, 445, 640, 905, 1256rpm

Reverse Speed: 110rpm

Related Names

Hard Rock Drill | Pneumatic Drilling Tool | Multi Stage Drilling Machine

Links:https://globefindpro.com/products/81282.html

-

XYD-3 Crawler-Mounted Water Well Drilling Rig

XYD-3 Crawler-Mounted Water Well Drilling Rig

-

BW-160 Mud Pump

BW-160 Mud Pump

-

60W 12/24V LED Driver

60W 12/24V LED Driver

-

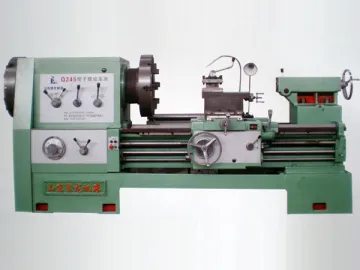

Q245 Pipe Threading Lathe Machine

Q245 Pipe Threading Lathe Machine

-

25W-100W Waterproof LED Driver

25W-100W Waterproof LED Driver

-

QK1322 CNC Pipe Threading Lathe Machine

QK1322 CNC Pipe Threading Lathe Machine

-

150W 24V LED Driver

150W 24V LED Driver

-

Steel Single Bed

Steel Single Bed

-

CK1322 CNC Pipe Threading Lathe Machine

CK1322 CNC Pipe Threading Lathe Machine

-

Double Classroom Desk and Chair

Double Classroom Desk and Chair

-

kids' Trapezoid Table

kids' Trapezoid Table

-

Home Study Furniture Accessories

Home Study Furniture Accessories