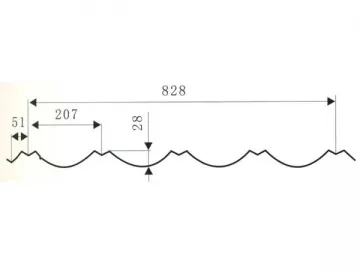

Corrugated Sheet Roll Forming Machine

The corrugated sheet roll forming machine is designed to manufacture high quality corrugated sheet, and the finished product has smooth and exquisite appearance. The corrugated sheet is widely used to build up roofs of industrial and civilian buildings, such as workshop, warehouse, hangar, gymnasium, theatre, engine house, exhibition hall, etc. In addition, this machine can be particularly designed when relevant drawings are provided.

Features

1. The feeding width includes 1000mm, 1200mm and 1250mm. So, steel coils that are bought from the raw material market could be processed by this machine without slitting treatment.

2. This corrugated sheet roll forming machine is a mature product, and it could work with curving machines.

Processing Flow

Passive decoiling → guided material feeding → roll forming → cut-to-length → offloading

Composition

1. 5T passive decoiler

2. Shape forming machine

3. Hydraulic shear

4. Hydraulic station

5. PLC control cabinet

6. Run out table

Specifications

| Model | GWC18-76-988 | GWC30-130-800 | Note |

| Applicable material | Color plate, galvalume sheet, aluminum plate and high-strength low-alloy steel plate | This machine is customizable upon each customer's requirements and the characteristics of processed material. | |

| Feeding width | 1000mm | ||

| Processing thickness | 0.3-0.8mm | ||

| Roller material | 45# steel coated with hard chrome | ||

| Main motor power / hydraulic station power | 7.5kW / 3kW | These parameters can be set according to the required production capacity. | |

| Forming passes | 20 | ||

| Forming speed | 5-15 meters/minute | ||

| Machine dimensions | 11×1.3×1.2m | 9×1.3×1.2m | |

| Machine weight | 7T | 9T | |

Related Names

Corrugated Roof Panel Machine | Steel Sheet Forming Equipment | Cold Rolled Sheet Making Machine

Links:https://globefindpro.com/products/81394.html

-

PE Printable Protection Film

PE Printable Protection Film

-

GWC40-205-1025 Glazed Roof Tile Roll Forming Machine

GWC40-205-1025 Glazed Roof Tile Roll Forming Machine

-

Glazed Roof Tile

Glazed Roof Tile

-

Roller Shutter Roll Forming Machine

Roller Shutter Roll Forming Machine

-

Steel Coil Slitting Line

Steel Coil Slitting Line

-

GWC14.5-80-1120 Assembled Silo Corrugated Sheet Roll Forming Machine

GWC14.5-80-1120 Assembled Silo Corrugated Sheet Roll Forming Machine

-

Decoiler

Decoiler

-

Carriage Board Roll Forming Machine

Carriage Board Roll Forming Machine

-

Bemo Panel Roll Forming Machine

Bemo Panel Roll Forming Machine

-

K-span Roll Forming Machine

K-span Roll Forming Machine

-

Stacker

Stacker

-

Automobile Chassis Roll Forming Machine

Automobile Chassis Roll Forming Machine