Automatic Oil Filling Machine

Features

1. YXT-YGO automatic oil filling machine is an automated packaging system that uses plunger pump and stainless steel valve to fill materials of different viscosity.

2. The plunger pump is pneumatically controlled via the stainless steel valve. The metering adjustment is convenient and reliable.

3. A high level liquid barrel is added to the automatic oil filler. Materials’ feeding is automatically controlled by a switch.

4. Our automatic oil filling machine applies the pneumatic needle, suck-back function of which can effectively avoid wiredrawing and leakage.

5. The whole oil machinery is convenient to clean and disinfect. Its specification is conveniently adjusted to suit for different filling applications.

6. With the frequency control, the machine stops working when there is no need for filling.

7. The entire edible oil filling machine is designed in accordance with GMP standard.

Parameters of the Automatic Oil Filling Machine

| Filling Head | Four-head, Eight-head, Twelve-head (It can be customized) |

| Production Capacity | Four-head unit: ≥ 15 bottles / min; Eight-head unit: ≥ 30 bottles / min; Twelve-head unit: ≥ 50 bottles / min |

| Filling Volume | 1000-5000ml |

| Filling Error | ≤ 1% |

| Compressed Air Pressure | ≤ 0.4-0.6Mpa |

| Power Supply | 220V 50Hz |

| Power Consumption | ≤ 1.2Kw |

| Net Weight | ≤1000kg |

Links:https://globefindpro.com/products/81602.html

-

CE4 V3 Atomizer

CE4 V3 Atomizer

-

510-T Atomizer

510-T Atomizer

-

Electronic Cigarette Leather Mini Pouch with Lanyard

Electronic Cigarette Leather Mini Pouch with Lanyard

-

Brother Atomizer

Brother Atomizer

-

Brother ECigarette

Brother ECigarette

-

EGO-T Atomizer

EGO-T Atomizer

-

Electronic Cigarette Chargers

Electronic Cigarette Chargers

-

Rotary Table

Rotary Table

-

Linear Bottle Rinser

Linear Bottle Rinser

-

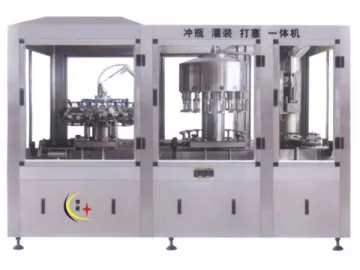

Bottle Washing, Filling and Capping Machine

Bottle Washing, Filling and Capping Machine

-

Bottle Rinsing, Filling and Capping Machine

Bottle Rinsing, Filling and Capping Machine

-

Semi-automatic Bottle Rinser

Semi-automatic Bottle Rinser