RBL2025B/2042B/2025BL/2042BL Glass Straight Line Double Edging Machine

Our glass straight line double edging machine mainly contains four models which are RBL2025B, RBL2042B, RBL2025BL, and RBL2042BL.

RBL2025B and RBL2042B are our newly developed products, and they show the advantages of high efficiency, high precision, reasonable price, safe and reliable running, etc. They are applied to grind flat glass and common laminated glass with different specifications, and they are very suitable for batch production and scale production.

As for the other two models, namely RBL2025BL and RBL2042BL, they also fit for batch production and scale production, and they are used to process flat glass, common laminated glass, and low-E glass.

Technical Parameters| Model | RBL2025B | RBL2042B | RBL2025BL | RBL2042BL |

| Glass thickness (mm) | 3-25 | 3-25 | 3-25 | 3-25 |

| Min. processing width (mm) | 250 | 250 | 250 | 250 |

| Max. processing width (mm) | 2500 | 4200 | 2500 | 4200 |

| Max. hemline grinding amount (mm) | 5 (one side) | 5 (one side) | 5 (one side) | 5 (one side) |

| Max. arris grinding amount (mm) | 3 | 3 | 3 | 3 |

| Feeding speed (m/min) | 1-6.5 | 1-6.5 | 1-6.5 | 1-6.5 |

| Slide grinding head group speed (mm/min) | 700 | 700 | 700 | 700 |

| Working height (mm) | 900 | 900 | 900 | 900 |

| Overall size (mm) | 5100×5200×1800 | 5100×6900×1800 | ||

| Power supply | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Compressed air pressure (MPa) | ≥0.6 | ≥0.6 | ≥0.6 | ≥0.6 |

| Air blowing rate (m3/min) | 894-1264 | 894-1264 | 894-1264 | 894-1264 |

| Output capacity of water pump (m3/h) | 12×2 | 12×2 | 12×2 | 12×2 |

| Total power (kW) | 53.47 | 53.47 | 56.77 | 56.77 |

| Max. film removing width (mm) | / | / | 15 | 15 |

| Film removing precision (mm) | / | / | ±0.3 | ±0.3 |

Deployment Diagram of Motors and Grinding Wheels

RBL2025B / RBL2042B

RBL2025BL / RBL2042BL (with CE certificated film removing wheel)

Main Components

1. The opening and closing operations of this glass double edging machine are achieved with the help of ball screw and straight line guide rail. The opening and closing are automatically controlled with excellent repositioning precision.

2. The grinding wheel adopts double V type guide rail, and it offers stable and precise performance with small vibration.

3. The polishing process adopts semi-automatic compensation.

4. For chamfering treatment, the ball screw and linear guide are applied to achieve automatic upward and downward motions with precise positioning and simple operation.

5. The cleat bracket is designed to move in the vertical direction automatically, and the movement range can reach up to 120mm. In addition, it is very convenient to change the grinding wheel.

6. The main transmission drive takes advantage of mechanical frequency conversion technology to control the speed, and it is upper placed which is a novel design. So, the replacement and maintenance for the belt can be finished easily.

7. Our glass straight line double edging machine uses annular synchronous belt and pneumatic positioning device to transport the glass, realizing steady delivery and precise positioning.

8. Due to the human-machine interface and the high-end PLC control system, our product shows high automation degree, and the operation is quite simple.

Major Configurations

| Part | Description |

| Base and frame | The carbon steel receives welding, annealing and aging treatments on by one. |

| Conveyor plate | It is made of high quality carbon steel, and annealing treatment is also applied. |

| Guide rail plate | Fabricated in modules, this plate is made of macromolecular and wear resistant materials. |

| Motor for grinding head | ABB motor or CDQC motor |

| Linear guide rail | HIWIN, Taiwan |

| Ball screw | ABBA, Taiwan |

| Timing belt | Barbieri or Megadyne, Italy |

| Synchronous belt | 45# steel coated with hard chrome |

| Transducer | Emerson, USA |

| Rotary switch and emergency stop | These parts are supplied by Jiangyin Changjiang Electric Appliance Co., Ltd. and Guangzhou Benlee Industrial Switch Manufacture Co., Ltd. |

| Photoelectric switch and intermediate relay | Omron, Japan |

| PLC | Delta, Taiwan |

| Human-machine interface | Hitech, Taiwan |

| Rotary encoder | Autonics, Korea |

| Transformer | Juche Electric Appliances Co., Ltd. |

| Low-voltage circuit breaker and contactor | CHINT Electronics Co., Ltd. |

Acceptance Standard

1. Glass Processing Standard

a. Parallelism error of flat glass: ≤3mm

b: Thickness error of flat glass: ≤0.1mm

2. Equipment Acceptance Standard

a. Parallelism error of two opposite edges: ≤0.2mm/m

b. Diagonal error of glass: ≤0.5 mm/m

c. Chamfer width error: ≤0.2mm/m

d. Other requirements: The machine should work in a smooth and stable way. The grinding angle and polishing effect should be uniform without any scratch, white dot, line finish, broken edge, etc.

Related Names

Glass Edge Grinder | Industrial Polishing Machine | Glass Grinding Equipment

Links:https://globefindpro.com/products/82403.html

-

XD935 3T Underground Mining Loader

XD935 3T Underground Mining Loader

-

RZS2018 Stroke Sander

RZS2018 Stroke Sander

-

XD918F 0.8T High Dump Bucket Loader

XD918F 0.8T High Dump Bucket Loader

-

XD918F 1.6T Log Grabber

XD918F 1.6T Log Grabber

-

RMD2720 Universal Grinder

RMD2720 Universal Grinder

-

XD926G 1T High Dump Bucket Loader

XD926G 1T High Dump Bucket Loader

-

Bale Spike

Bale Spike

-

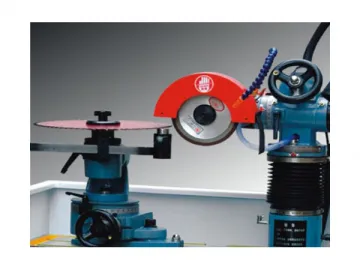

RMD1108 Economical Circular Saw Blade Grinder

RMD1108 Economical Circular Saw Blade Grinder

-

Tooth Bucket

Tooth Bucket

-

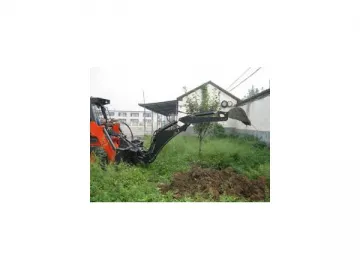

Side Shift Backhoe

Side Shift Backhoe

-

XD920F 1.6T Off-Road Fork Loader

XD920F 1.6T Off-Road Fork Loader

-

Industrial Grapple

Industrial Grapple