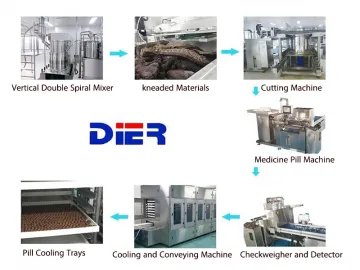

Fully Automatic Traditional Chinese Medicine Pill Production Line

Our fully automatic traditional Chinese medicine pill production line is capable of accomplishing production process from material mixing, blending, kneading, granulation, to finial drugs drying. The entire production process is automatically carried out, significantly improving production efficiency while reducing labor intensity. Finished pills are featured by stable medicinal properties in compliance with GMP requirements.

Model: HF-200 Production capacity: 400-450kg/h Total power: 6kw Dimension: 2200×1800×2200mm Overall Weight: 1000kg Functions & Advantages: Blending powder inside drum, enabling the powder to be highly uniform blended Planetary mixer with bottom discharge system

Model: GHC-300 Production capacity: 1500-2500kg/h Total power: 8.5kw Dimension: 1900×1300×1800mm Overall Weight: 2000kg Functions & Advantages: Short blending time, high efficiency, automatic bottom discharge Chinese medicine kneader (double-layer)

Model: GSL-450 Production capacity: 400-500kg/h Total power: 15kw Dimension: 2100×710×1390mm Overall Weight: 700kg Functions & Advantages: Increasing viscosity and evenness of medicine Automatic horizontal granulator

Model: WZ-180 Production capacity: 80-180kg/h Total power: 6.5kw Dimension: 1950×880×1630mm Overall Weight: 1200kg Functions & Advantages: Output is varying according to properties and shapes of pills Automatic powder distributing machine

Model: BF-300 Production capacity: 250-300kg/h Total power: 0.12kw Dimension: 900×600×800mm Overall Weight: 100kg Functions & Advantages: Automatic powdering on the wet pill to form a non-stick layer, and the powder is reusable Pill rounding machine

Model: QGZ-06 Production capacity: Matched capacity Total power: 3kw Dimension: 5080×1050×1365mm Overall Weight: 900kg Functions & Advantages: Can be equipped with 4-12 tanks according to required productivity Drum-type pill sieving machine

Model: SWJ-Ⅰ Production capacity: 100-300kg/h Total power: 0.55kw Dimension: 2500×1100×1600mm Overall Weight: 300kg Functions & Advantages: 2 sectional sieving drum, square sieving hole Tunnel type microwave drying & sterilizing machine

Model: SWG-40-5 Production capacity: Dewatering≥30kg/h Total power: 40kw(Adjustable) Dimension: 12840×1750×2200mm Overall Weight: 3000kg Functions & Advantages: Microwave energy is selectable according to initial water content and required productivity Centrifugal pill sieving machine

Model: XW-Ⅱ Production capacity: 200-300kg/h Total power: 50HZkw Dimension: 1330×1330×2860mm Overall Weight: 180kg Functions & Advantages: Two types of sieving machine is available according to pill shapes Coating machine (for sugar coated pills)

Model: BY-1000 Production capacity: 50-80kg/h Total power: 2.5kw Dimension: 1350×100×1900mm Overall Weight: 500kg Functions & Advantages: After drying process, pills are coated and colored

This granulation line is fabricated for production of traditional Chinese medicine large pills. The drug production line mainly consists of mixer, granulator, manipulator inspection system, pill lifting unit, etc., achieving complete automatic in-line production process for traditional Chinese medicine pills, including mixing, blending, granulation, cooling, shell packaging, wax coating, printing, blister packaging, and cartoning.

Single Machines Powder blender Centrifugal pill sieving machine Drum-type pill sieving machine Centrifugal pill sieving machine Features Vertical planetary mixing with dual stirrer blades, automatic adding of ingredients, uniform mixing and blending; Raw materials are automatically pre-processed, extruded and cut into sheet shape; Six pill rollers are fully automatic servo driven, ensuring that the drug strips are fed out in a uniform speed; Pills are automatically inspected and weighed by manipulator, the unqualified pills are automatically rejected, eliminating the need for manual inspection; Tray type cooling unit automatically accomplishes pill loading, cooling and unloading, the trays are easy to clean; Production ProcessesPowder Blending → Mixing (bottom discharge) → Kneading → Granulation → Cooling → Rounding (round pill shaping) → Sieving (drum type) → Microwave drying → Sieving (centrifugal type) → Coating → Finished Pills

Links:https://globefindpro.com/products/8246.html

-

Tunnel Multi-layer Microwave Drying Sterilizing Machine

Tunnel Multi-layer Microwave Drying Sterilizing Machine

-

Wax Shell Packaging Machine

Wax Shell Packaging Machine

-

Pipe Conveying System for Cutting Band Saw Machine

Pipe Conveying System for Cutting Band Saw Machine

-

Outfeed Conveyor with Cooling Fan

Outfeed Conveyor with Cooling Fan

-

Pipeline End Beveling Machine

Pipeline End Beveling Machine

-

Pipe Conveying System for End Beveling Machine

Pipe Conveying System for End Beveling Machine

-

XQJ Series Bottom Discharge Planetary Mixer

XQJ Series Bottom Discharge Planetary Mixer

-

Wax Coating Machine

Wax Coating Machine

-

Pharmaceutical Granulation Line (for Large Pills)

Pharmaceutical Granulation Line (for Large Pills)

-

High Speed Fully Automatic Bottling Line

High Speed Fully Automatic Bottling Line

-

Pipe Fabrication Shop Building and Operating

Pipe Fabrication Shop Building and Operating

-

Vertical Stick Pack Packaging Machine

Vertical Stick Pack Packaging Machine