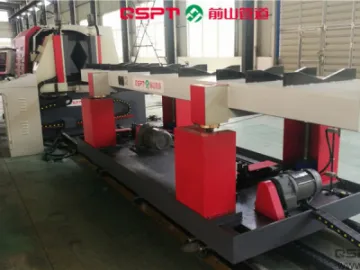

Pipe Plasma Beveling and Cutting Machine (Roller Bench Type)

Model: BPPBM-24A

(1). Structure: Three line roller with fixed distance

(2). Roller Bench Length:7000MM

(3). Driving System: Servo motor precision reducer

(4). Rev: 0-2.5M/Min (VF stepless speed adjustment)

(5). Roller Bench Material: 45#, Surface bluing treatment

(6). Rotation Accuracy: <2.0MM Trolley System:

(1). Trolley Stroke: 6350MM (moving lengthwise)

(2). Cutting Torch Travel: 700MM (up/down); 300MM (left/right)

(3). Cutting With: Plasma cutting (can be equipped for flame cutting)

(4). Cutting Torch Angle: ±45° (adjustable)

(5). Cutting Torch Quantity: One piece of plasma cutting torch

(6). Angle Error: <2°

(7). Length Fixing Accuracy: <2.0MM Control System: SH-2000H CNC Cutting System Length-Measuring System: CNC length measuring which is included in the control system Conveying System: Built in conveying system equipped with a lifter; additionally, one set of conveying system can be provided for bevel cutting machine if necessary and conveying can be implemented manually or electrically Cutting Power: Our OEM products which are famous in China (or as per customers' demands) Features The pipe plasma beveling and cutting machine offers good on-line performance (designed as per the on-line equipment of the production line). It offers a beveling speed of ≤2Min/pipe bevel (DN200 SCH40). It has bevel cutting of: cutting off and with one bevel of the pipe simultaneously. The pipe plasma beveling and cutting machine offers good bevel quality.

Scan QR to Read

Links:https://globefindpro.com/products/8254.html

Links:https://globefindpro.com/products/8254.html

Recommended Products

-

Traditional Chinese Medicine Pill Machine (for Large Pills)

Traditional Chinese Medicine Pill Machine (for Large Pills)

-

Automatic Wax Shell Printing Machine (for traditional Chinese medicine pills)

Automatic Wax Shell Printing Machine (for traditional Chinese medicine pills)

-

Marble Look tile- DOHA

Marble Look tile- DOHA

-

Marble Look tile- Sapphires

Marble Look tile- Sapphires

-

Marble Look tile- Lago

Marble Look tile- Lago

-

Tablet Coating Machine/ Polishing Machine

Tablet Coating Machine/ Polishing Machine

-

Pharmaceutical Granulation Line (for Small Pills)

Pharmaceutical Granulation Line (for Small Pills)

-

Pipe Conveying System for End Beveling Machine

Pipe Conveying System for End Beveling Machine

-

Pipeline End Beveling Machine

Pipeline End Beveling Machine

-

Outfeed Conveyor with Cooling Fan

Outfeed Conveyor with Cooling Fan

-

Pipe Conveying System for Cutting Band Saw Machine

Pipe Conveying System for Cutting Band Saw Machine

-

Wax Shell Packaging Machine

Wax Shell Packaging Machine

Hot Products