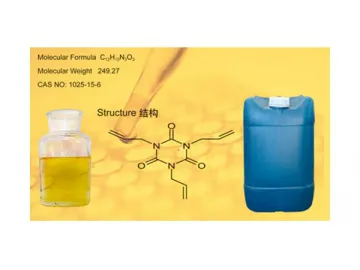

Triallyl Isocyanurate (TAIC)

Brief Introduction

| Molecular Formula | C12H15N3O3 |

| Molecular Weight | 249.27 |

| CAS No. | 1025-15-6 |

Physical and Chemical Properties

| Appearance | Colorless or light yellow liquidAt normal temperature (25°C), it is colorless liquid or hexagonal crystal |

| Purity ≥ % | 98 |

| Melting Point ℃ | 23-26 |

| Acid Value KOH mg/g ≤ | 0.5 |

| Specific Gravity | 1.155 (30°C) |

| Boiling Point | 144°C/3mmHg297°C/760mmHg |

| Flash Point | 355°C |

| Viscosity | 83±3 centipoise (30°C) |

| Solubility | It is insoluble in water, and slightly soluble in alkane. In addition, it is easily soluble in ethanol, acetone, cyclopentene, halogenated hydrocarbon, aromatic hydrocarbon, and more. |

Wide Applications

1. The triallyl isocyanurate can be used as the cross-linking agent of diversified thermoplastics, such as PE, PVC, CPE, EVA, PS and some others. For thermo cross-linking, its common dose ranges from 1% to 3%, and the dose of dicumyl peroxide (DCP) varies from 0.2% to 1%. For radiation cross-linking, the dosage is 0.5-2%, and there is no need to add DCP.

After cross-linking, various properties of manufactured goods can be significantly improved, including heat resistance, fire resistance, solvent resistance, mechanical strength, and electrical property, among others. In comparison with peroxide system, our product can enormously improve the product quality and produce no abnormal odor. It is typically applied in PE, PE/CPE, PE/EVA, cross-linked cable, as well as high or low-foam PE goods.

2. In addition, TAIC serves as the co-curing agent of a variety of special rubber, such as EPR, CPE, and all sorts of fluororubber, among others. When coordinated with DCP, the common dosage of our product is 0.5-4%. This product can greatly shorten the curing time, and also enhance the strength, wear resistance, solvent resistance, and corrosion resistance.

3. Triallyl isocyanurate also functions as the cross-linking agent of the acrylic-acid or styrene type ion exchange resin. Compared with divinylbenzene cross-linking agent, this product features less dosage and higher quality. It can be applied in the preparation of the ion exchange resin with such outstanding properties as high strength, large aperture, as well as strong resistance to heat, acids, alkalis, oxidation and contamination. Our product is the newly developed ion exchange resin with superb prospect.

4. Moreover, the TAIC acts as a modifier of polyacrylate, polyalkyl acrylate, and more. It can dramatically improve the heat resistance, optical property, processing performance and some others. It is typically used for the heat-resistant modification of common organic glass.

5. As a modifying agent of epoxy resin or DAP (poly diallyl phthalate) resin, the TAIC can improve the heat resistance, adhesiveness, mechanical strength, and dimensional stability. A typical example of use is the modification of epoxy potting compounds and encapsulants.

6. The triallyl isocyanurate is also used as the cross-linking agent and modifying agent of unsaturated polyester and thermoplastic polyester. It can remarkably improve the heat resistance, chemical resistance, dimensional stability, weather resistance, mechanical property, and more. This product is often used to enhance the heat resistance of the hot-press type fiber reinforced unsaturated polyester goods. The modified goods can offer the operating temperature of over 180 degrees Celsius.

7. The homopolymer of TAIC is called poly (triallyl isocyanurate). It is a kind of transparent resin with high firmness, strong heat resistance, and distinguished electrical insulation. It can be also used for bonding glass and ceramic, among others. This substance is typically used for the manufacturing of multi-layered safety glass.

8. The triallyl isocyanurate can function as the internal plasticizer of polystyrene. Transparent and shatter-resistant goods can be manufactured through the copolymerization modification of styrene, TAIC and some others.

9. Furthermore, the triallyl isocyanurate can be considered as the protective agent that can resist heat, radiation and climate. The TAIC prepolymer is used for the baking finish of metal surface. The coated film is provided with outstanding electrical insulating property, as well as ultra strong resistance to heat, radiation and climate. It is often used for the production of such insulating materials as the printed substrate of micro-electronics goods.

10. At last, the triallyl isocyanurate can serve as the intermediate of such products as photocurable coating, photoresist, flame retardant, and fireproof cross-linking agent, among others. It is representatively used for the synthesizing of high-efficiency flame retardant TBC and fireproof cross-linking agent DABC.

Packaging and Storage

The triallyl isocyanurate is wrapped in a PE plastic drum. The net weight of each drum is 25kg or 200kg. TAIC is stored and transported as a non-toxic and non-dangerous product. It should avoid the high-temperature sun exposure.

Related Names

Thermoplastic Agents | Rubber Vulcanizing Agent | Industrial Intermediate

Links:https://globefindpro.com/products/82759.html

-

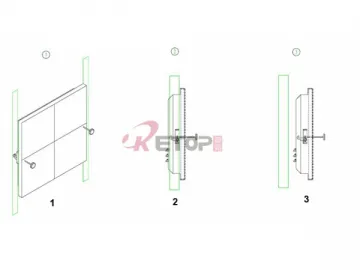

Removable Front Panel LED Display

Removable Front Panel LED Display

-

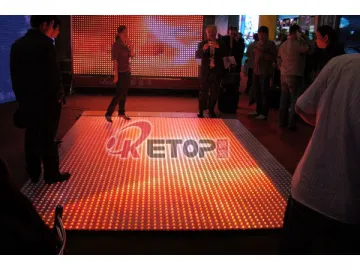

Dance Floor LED Display

Dance Floor LED Display

-

Magnesium Sulphate Trihydrate & Magnesium Sulphate Dihydrate

Magnesium Sulphate Trihydrate & Magnesium Sulphate Dihydrate

-

Pop-up Stand LED Display

Pop-up Stand LED Display

-

8mm Outdoor Rental LED Display(640*640)

8mm Outdoor Rental LED Display(640*640)

-

Magnesium Sulphate Monohydrate

Magnesium Sulphate Monohydrate

-

Perimeter LED Display

Perimeter LED Display

-

Mesh LED Display

Mesh LED Display

-

Center Hung Cube LED Display

Center Hung Cube LED Display

-

Fascia LED Display

Fascia LED Display

-

Standard Advertising LED Display

Standard Advertising LED Display

-

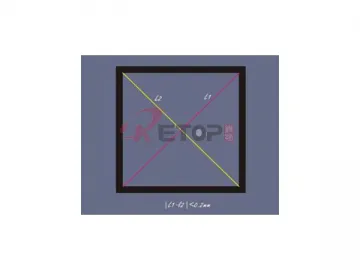

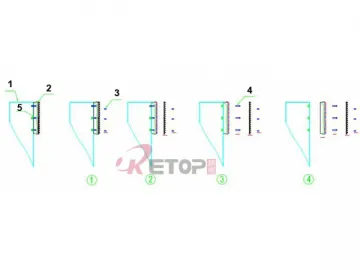

Front Removable Tile

Front Removable Tile