PVC Granule for Electronic Conducting Tube

28 ~ 54

Shore A Hardness

ASTM D2240

75 ~ 100

Shrinkage Rate %

23 ℃

0.1 ~ 0.3

Surface Resistance Value

MODEL 385

103 ~ 5 Ω

Shape

Visual

Granular

The characteristic index of specific product model can be got from the internet-sales backstage staff.

Melting Temperature Range

Extrusion molding melt temperature: 158 ~ 180 ℃ (316~356F)

Melting Temperature Range

Injection molding melt temperature : 175 ~ 195 ℃ (355~383F)

Measurement Unit Conversion

1ft . lb/inch = 53.1 J/m 1J/m=0.1Kgcm/cm 1Kgf/mm2=1.422Psi

Introduction to Product Model and Uses

Model | Main Performance and Uses |

ED-300H series | This type PVC granule is mostly used to produce all kinds of rigid antistatic packaging products by common extrusion process. Currently, it is widely applicable to the IC electronic packaging products and other rigid PVC extruded products requiring static-free performance. |

DM-300H series | DM-300H series is suitable for the production of various rigid antistatic packaging products by injection molding process. At present, it is extensively applied to coal mine underground pipes, valves, hooks, as well as the rigid PVC accessories in demand for antistatic property. |

ED-800H series | ED-800H series is primarily used to make all sorts of soft antistatic conducting tubes, closed seals, and other products by adopting common extrusion process. |

DM-800H series | DM-800H series is appropriate for the production of various soft antistaticaccessories by means of injection molding technique. It can be widely found in the coal mine underground soft PVC injection products which require static-free performance. |

Characteristics

Our PVC granule for electronic conducting tube is ideal for all kinds of PVC extrusion or injection molding production process. Its hardness can be customized in accordance with customer requirement.

Moreover, this granule possesses extremely good surface glossiness and high strength. With distinguished conductivity, it can make the surface resistance value reach up to 103~5Ω. Its material can meet the needs of European Union ROSH environmental protection standard.

Information on Safe Use

1. Before production, the extrusion equipment should be cleaned and experience the thermal insulation treatment.

2. The processing temperature should be set according to different processing equipment and production speed. In each stage, the processing temperature of extruder generally varies from 155 to 175℃.

3. Our PVC granule should be stored in a dry and ventilated storehouse and keep away from the ground. Its quality guarantee period is one year.

Precautions

Once the molding process is finished, gas will be produced. Then, it will cause damage to eyes, skin, and respiratory organ. To avoid being absorbed, the gas had better be partly discharged. Before use, the material safety data sheet abbreviated as MSDS can be seen for reference.

Related Names

PVC Conductive Granule | Black PVC Compound | Electric Conduction PVC Composite Material | Conduction PVC Material

Links:https://globefindpro.com/products/83879.html

-

PVC Pipe Fittings

PVC Pipe Fittings

-

Artificial Leather

Artificial Leather

-

PVC Granules for UPVC Profiles

PVC Granules for UPVC Profiles

-

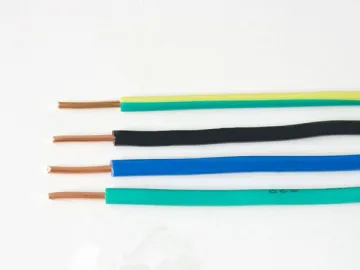

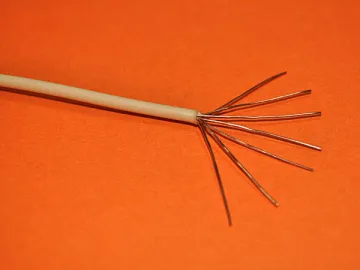

Building Wire (BV, BVR, BLV etc)

Building Wire (BV, BVR, BLV etc)

-

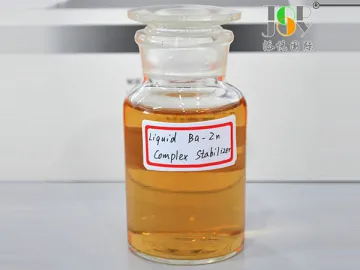

Barium-Zinc Stabilizer for PVC

Barium-Zinc Stabilizer for PVC

-

PVC Granules for Heat Shrink Film

PVC Granules for Heat Shrink Film

-

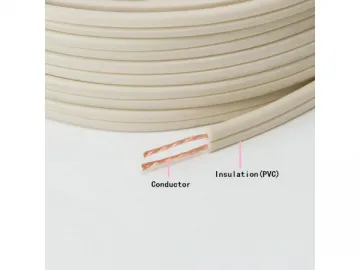

Flat Cable for Fixed Wiring (BVVB BLVVB)

Flat Cable for Fixed Wiring (BVVB BLVVB)

-

Foot Mat

Foot Mat

-

Rechargeable Heated Insole

Rechargeable Heated Insole

-

Fire Resistant PVC Insulated and Sheathed Control Cable

Fire Resistant PVC Insulated and Sheathed Control Cable

-

Speaker Cable (Audio Cable)

Speaker Cable (Audio Cable)

-

YHGZFJ-B-8 Liquid Filling Machine

YHGZFJ-B-8 Liquid Filling Machine