Cold Drawn Seamless Pipe

The cold drawn seamless pipe is often used in the mechanical structure and hydraulic equipment, where high dimensional accuracy and good surface finish are called for. Cold drawing refers to a process done at room temperature, whereby the steel plate or strip steel is pulled, bent, and drawn to form various shapes.

General Flow of Manufacturing Process

Solid Round Billet-Heating - Perforating - Heading - Annealing - Pickling - Oil Coating (Copper Plating) - Cold Drawing in Multiple Passes (Cold Rolling) - Semi-Finished Pipe - Heat Treatment - Straightening - Hydrostatic Testing(Non-Destructive Detection) - Marking - Acceptance into Warehouse

Differences between Hot-Rolled Pipe and Cold-Drawn Pipe

Steel tubes often need to be drawn several times in order to produce the required shape and tolerance. Between each drawing pass, the material should be annealed to restore some ductility and prepare it for further processing. From the outside, you can see that the cold-drawn seamless pipe is in small diameter below 127mm while the hot-rolled pipe has larger diameter. In fact, cold-drawn seamless pipe usually has higher precision than the hot-rolled type. Associatively, cold-drawn pipes cost higher than hot-rolled version.

Cold-drawn seamless pipes are the among the most strictly regulated pipe products in terms of outside diameter, wall thickness, and surface finish. They can be divided into different types: ordinary steel pipe, pipe for low-, medium-, and high-pressure boiler, alloy steel tube, stainless steel pipe, pipe for oil cracking application, thin-walled carbon steel pipe, thin-wall alloy steel tube, thin-wall stainless steel tube, and irregularly-shaped steel tube.

1 Process: cold drawing

2 Standards: GB/T8162/8163/3087/5310, ASME B36 10, ASTM A106/A53, ASTM

A179, API 5L/5CT, EN10210/10219

3 Specification:

OD: 21.3~127mm

WT: SCH10-SCHXXS

4 Materials: 10#, 20#,45#,16Mn, GRB, Q345B, X42-56, ST44, ST52 etc.

5 Testing: Eddy current, Hydrostatic, Ultrasonic, Intergranular corrosion etc.

6 Packing: in bundles with steel strips, seaworthy packing as per customer's requirements

We have been working on the pipe product manufacturing and export business for many years. Our hard work and dedication has won us a good reputation among domestic steel pipe industry. Currently, we are maintaining collaborative relationships with many big steel companies. Our products have been highly praised with regard to our product quality and service, by our international customers from South Asia, Middle East, Europe, and America.

Continuous quality improvement is our survival strategy. First-clas service grants us long-term prosperous development. We sincerely encourage customers to cooperate with us, as we will strive to meet or exceed their expectations.

Related Names

Thin Wall Stainless Steel Tube | Mild Steel Pipe | Precision Steel Tubing

Links:https://globefindpro.com/products/86351.html

-

Shantui Bulldozer Ripper

Shantui Bulldozer Ripper

-

Komatsu Bulldozer Carrier Roller

Komatsu Bulldozer Carrier Roller

-

Komatsu Excavator Bucket

Komatsu Excavator Bucket

-

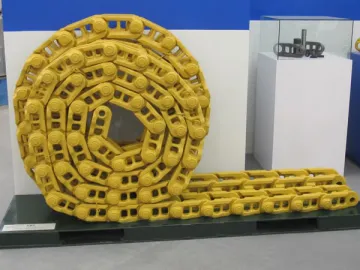

Komatsu Bulldozer Track Chain and Track Shoe

Komatsu Bulldozer Track Chain and Track Shoe

-

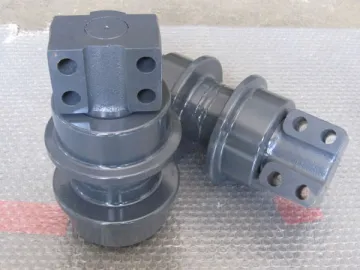

Komatsu Excavator Carrier Roller

Komatsu Excavator Carrier Roller

-

Komatsu Excavator Sprocket

Komatsu Excavator Sprocket

-

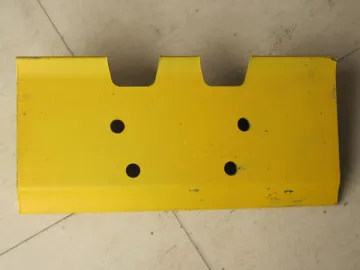

Komatsu Bulldozer Blade Cutting Edge

Komatsu Bulldozer Blade Cutting Edge

-

Undercarriage Parts

Undercarriage Parts

-

Work Equipment

Work Equipment

-

Shantui Bulldozer Idler

Shantui Bulldozer Idler

-

API Thread Protectors

API Thread Protectors

-

Hot-rolled Seamless Pipe

Hot-rolled Seamless Pipe