UV Coating Line for SPC Flooring Production

Surface Treatment System for Floor Panels  Request a Quote Technical Parameter

Request a Quote Technical Parameter

Component Equipment Hot Air Dryer Single Roller Coating Unit Tree Lamps UV Dryer Five Meter Heating and Leveling machine Five Lamps UV Drying Unit

This UV coating line is made up of a dryer, single-roll coater, leveler and other necessary equipment. The surface treatment line specializes in giving high-quality UV treatments to fiberboard, wood board and other panels. First, the wood board is polished then coated. Afterwards, the ultraviolet rays instantly dry the coating. Finally, the coating is polished a second time. This UV coating line hosts three separate control units, each of which has various features such as efficiency, convenience, energy savings and stability, and guarantees high safety.

| Description UV Coating Line (1500 MM) | |

| Delivery method | 1500 mm wide PVC belt (striped belt) |

| Conveying motor | 0.75 kW Shihlin Inverter |

| Electrostatic rod | 1500 mmL*1 |

| 4 Meter Heating & Leveling Machine | |

| Dimensions | 4000 * 1850 * 850 (250) mm |

| Delivery method | Stainless steel mesh belt 1500 mmW |

| Conveying motor | 0.75 kW Shihlin Inverter |

| Oven dimension | 3500*1700*250 mm |

| Temperature | about 50-100℃ |

| Full-Precision Single Roller Coating Machine | |

| Operation panel | 7-inch touch screen |

| Mechanical dimensions | 1760*3000*850 (700)mm |

| Coating wheel | Ø305 * 1650 mm * 1 piece /set |

| Uniform mirror wheel | Ø165 * 1650 mm * 1 piece / set |

| Coated bottom wheel | Ø200 * 1510 mm * 1 piece |

| Coating motor | 3 kW |

| Coated bottom wheel motor | 1.5 kW |

| Mirror wheel motor | 0.75 kW |

| Heating oil tank | 450 * 400 * 300 * 1 piece/ set |

| Conveying motor | 0.75 kW |

Scan QR to Read

Links:https://globefindpro.com/products/868.html

Links:https://globefindpro.com/products/868.html

Recommended Products

-

Ethyl Ester of β-Apo-8'-Carotenoic Acid

Ethyl Ester of β-Apo-8'-Carotenoic Acid

-

Vitamin E

Vitamin E

-

Wall Panel Double-End Tenoner Line

Wall Panel Double-End Tenoner Line

-

Bevel Painting and IXPE Backing Laminating Line

Bevel Painting and IXPE Backing Laminating Line

-

Multi-blade Rip Saw with Chain Feeding

Multi-blade Rip Saw with Chain Feeding

-

Flooring Edge Trimming & Bevel Cutting Line

Flooring Edge Trimming & Bevel Cutting Line

-

Vitamin C

Vitamin C

-

Taurine

Taurine

-

F63C Automatic Softener Valve

F63C Automatic Softener Valve

-

YC76 Pneumatic Automatic Hose Cutting Machine

YC76 Pneumatic Automatic Hose Cutting Machine

-

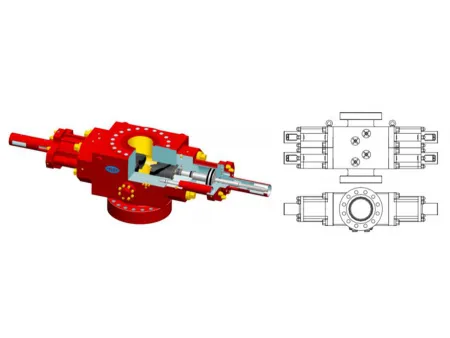

Ram BOP

Ram BOP

-

Daily Maintenance of Glass Lined Reactor

Daily Maintenance of Glass Lined Reactor

Hot Products