1.4301/1.4307/304L Stainless Steel Tubing

1.4301/1.4307/304L Stainless Steel Tubing

Apart from the old name18/8, 1.4301 or 1.4307 stainless steel tubing which is characterized bydistinct resistance to corrosion and heat, superior machinability as well as excellent weldability, is also known as grade304 or 304Lrespectively. It also can be used for cold or hot working. As the mostcommonly used stainless tube, our type 304 series which can be severely deepdrawn is mainly applied to sinks and saucepans.

As the low carbon version of 304, type 304L is suitable for heavy gauge components for itsenhanced weldability.Meanwhile, 304H with high carbon content is applicable for elevated temperatureuse as well. Our product may be available as dual certified material that is inline with the criteria for both 304 and 304L.

Specifications

| Chemical Composition | % Present |

| Carbon (C) | 0.0 - 0.03 |

| Chromium (Cr) | 17.50 - 19.50 |

| Manganese (Mn ) | 0.0 - 2.00 |

| Silicon (Si ) | 0.0 - 1.00 |

| Phosphorous (P) | 0.0 - 0.05 |

| Sulphur (S) | 0.0 - 0.02 |

| Nickel (Ni) | 8.00 - 10.50 |

| Iron (Fe) | Balance |

| Physical Property | Value |

| Density | 8.0 Kg /m³ |

| Melting Point | 1450 °C |

| Thermal Expansion | 17.2 x10^-6 /K |

| Modulus of Elasticity | 193 GPa |

| Thermal Conductivity | 16.2 W/m.K |

| Electrical Resistivity | 0.072 x10^-6 Ω .m |

| Mechanical Property | Value |

| Proof Stress | 200 Min MPa |

| Tensile Strength | 500 to 6070 MPa |

| Elongation | 45 Min % |

| Supplied Form | Sheet, Strip, Tube, Bar, Fittings & Flanges, Pipe, Plate |

| Designation | S30400, 304S11, EN58E |

| Remark: Above properties are for 1.4307 Property data given in this document is typical for flat rolled products covered by ASTM A240/A240M. ASTM, EN or other standards may cover products sold. It is reasonable to expect specifications in these standards to be similar but not necessarily identical to those given in this datasheet. | |

Particular ranges of sulphurcontent may provide improvement of particular properties. For machinability,a controlled sulphurcontent of 0.015 % to 0.030% is recommended and permitted. For weldability, a controlled sulphur content of 0.008 % to0.030 % is recommended and permitted. For polishability, a controlled sulphur maximum content of 0.015 % is recommended.

Elements not listed in this table shall not be intentionally added to the steelwithout the agreement of the purchaser except for finishing the cast.

EN10216-5 Seamless steel tubes for high pressure purposes-Technical deliveryconditions

EN 10088 – 2: 2005 Stainless steels. Technical delivery conditions forstainless steel sheet/plate and strip of corrosion resisting steels for generalpurposes

EN 10088 - 3: 2005 Stainless steels. Technical delivery conditions forsemi-finished products, bars, rods, wire, sections and bright products ofcorrosion resisting steels for general purposes

Links:https://globefindpro.com/products/87706.html

-

Boiler Steel Tube

Boiler Steel Tube

-

TP321 Stainless Steel Tube

TP321 Stainless Steel Tube

-

TP316/316L/316Ti Stainless Steel Seamless Tube

TP316/316L/316Ti Stainless Steel Seamless Tube

-

Economic Intelligent Vehicle Digital Video Recorder

Economic Intelligent Vehicle Digital Video Recorder

-

UNS S32750 /1.4410 /2507 Super Duplex Stainless Steel Pipe

UNS S32750 /1.4410 /2507 Super Duplex Stainless Steel Pipe

-

People Counting Camera

People Counting Camera

-

UNS S32305/S31803/2205 Duplex Stainless Steel Pipe

UNS S32305/S31803/2205 Duplex Stainless Steel Pipe

-

Intelligent Vehicle DVR

Intelligent Vehicle DVR

-

Heat Exchanger Tube (SMLS Steel Tube)

Heat Exchanger Tube (SMLS Steel Tube)

-

TP317L High Pressure Stainless Steel Pipe

TP317L High Pressure Stainless Steel Pipe

-

Welded Steel Condenser Tube

Welded Steel Condenser Tube

-

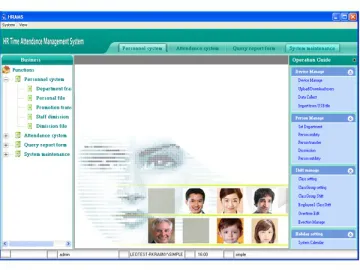

Time Attendance Software

Time Attendance Software