Fully Automatic High Speed Water-Based Laminator / Laminating Machine

MODEL: SDFM-1100 Fully Automatic high-speed water-base Laminator

MAIN SPECIFICATION:

MODEL | SDFM-1100 |

Max.Paper size | 1100 ×1200mm |

Min.paper size | 300 ×300mm |

Laminating speed | 10-65m/min |

Paper thickness | 100-500gsm |

Gross power | 60kw |

weight | 9000kgs |

Deminsion | 13000 ×2600 ×3100mm |

Main Features:

This machine SDFM-1100 Fully Automatic High-speed water-base Laminator machine which is designed mainly for the lamination of water-base glue film, and also suits the lamination of oily glue film, pre-glued film as well as glueless film. One machine can have four purposes. The film shall be coated first with water-base glue and then dried through the big drying roller. Meanwhile, automatic feeder equipped with paper length controller conveys paper sheets to laminating unit. Then the coated film will be laminated on paper surface by the heating and pressure of perssuring roller. The big drying roller and pressure roller adopt hot water circulation system with quick temperature rise and stable and precise temprerature control. The laminated products can be winded directly or through perforating wheel and separating system be cut into paper sheets. Paper sheets can be received with manual table or automatic paper stacker.

Applications

The multi-functional laminator suits water-base lamination, oil-base lamination, glueless film lamination and pe-glued film lamination.

CONFIGURATION:

1. Pre-stack paper feeder improves working efficiency; belt conveyor furnished with air aspirator regulates conveyed paper sheets much better.

2. Dusting system clears efficiently dust on paper surface, and perfects laminating quality so much.

3. Big diameter of mirror laminating roller is equipped with water cycle heating system.

4. Ceramic, which is netlike design, furnished with frequency converter can adjust the speed independently. What's more, it could make coating more even and avoid wasting the glue.

5. Film release device is equipped with air expansion shaft and clutch to control film tension.

6. The adjustable air expansion shaft can load and release the film more conveniently. It's easy to operate. In addition, it will not make the coating with glue corrugated while running.

7. Pneumatic paper collector can be adjusted easily upon needs, and receives paper sheets regularly.

8. The imported servo motor and Taiwan side lay which can be adjusted could effciently keep the machine running precisely.

Links:https://globefindpro.com/products/88690.html

-

Cardboard Die Cutting Machine

Cardboard Die Cutting Machine

-

SQZ-130CTN Double Hydraulic Paper Cutting Machine

SQZ-130CTN Double Hydraulic Paper Cutting Machine

-

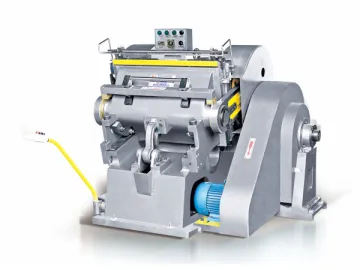

TYMK-930 Die Cutting Hot Stamping Machine

TYMK-930 Die Cutting Hot Stamping Machine

-

SQZ-130CT Fully Automatic Hydraulic Paper Cutting Machine

SQZ-130CT Fully Automatic Hydraulic Paper Cutting Machine

-

Paper Die Cutting Machine

Paper Die Cutting Machine

-

Leather Die Cutting Machine

Leather Die Cutting Machine

-

SQZ-176CTN Double Hydraulic Paper Cutting Machine

SQZ-176CTN Double Hydraulic Paper Cutting Machine

-

SQZ-155CTN Double Hydraulic Paper Cutting Machine

SQZ-155CTN Double Hydraulic Paper Cutting Machine

-

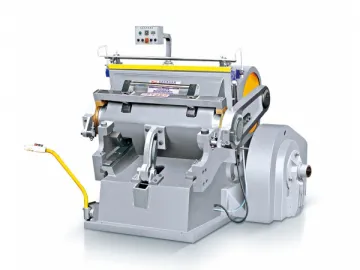

TYMK-1100 Die Cutting Hot Stamping Machine

TYMK-1100 Die Cutting Hot Stamping Machine

-

High Precision and Multi-duty Laminator / Laminating Machine

High Precision and Multi-duty Laminator / Laminating Machine

-

ML-2000 Die Cut Machine

ML-2000 Die Cut Machine

-

SQZ-115CTN Double Hydraulic Paper Cutting Machine

SQZ-115CTN Double Hydraulic Paper Cutting Machine