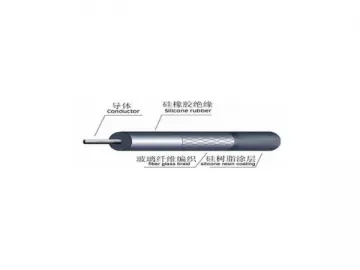

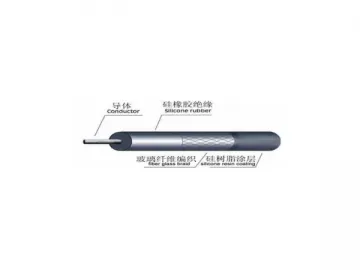

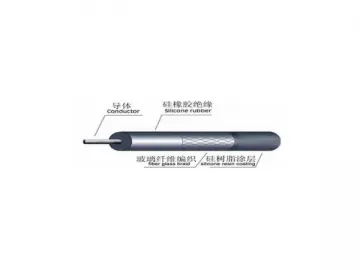

AGR Silicone Rubber Insulation Installation Wire

AGR Silicone Rubber Insulation Installation Wire

Our AGR silicone rubber insulation installation wire is equippedwith tin coated copper wire conductor. We take use of silicone rubber to makeits insulator. This wire needs 500V voltage to work normally and it can affordthe high temperature of 180℃.The cross sectional area of the wire product we produce has severalspecifications ranging from 0.2mm2to 25mm2.As known to all, the bigger cross sectional area is, the thicker should thesilicone rubber layer be. The tensile strength is over 5.0N/mm2 beforethe wire is ageing treated. After being treated in the environment of 200℃,three Celsius degrees plus or minus, for 240 hours, the tensile strength of ourproduct still be over 4.0 N/mm2. Therefore, our silicone rubberinsulation installation wire has quite long service life.

Wire Lettering:AGR 0.2mm²~25mm² 180℃ 500V HUA CHENG CABLE

| Items | Technical datas | Applied standard | ||

| Outer appearance | Smooth, even, without loose | Q/320281ANX01-2006 GB 5013.3-1997 | ||

| Spark test | AC6KV/ 0.15 S | |||

| Vol. test | 2 KV/15 min | |||

| mechanical properties of insulation material | Before aging | Tensile strength | ≥5.0N/mm² | |

| elongation at break | ≥150% | |||

| After aging | Tensile strength | ≥4.0N/mm² | ||

| (200±3℃×240h) | elongation at break | ≥120% | ||

| Poisonous substance control | Comply with ROHS rule | EU—2002/95/EC | ||

| AGR | |||||||

| section | Conductor | Insulation | Wire OD | Conductor Resistance | |||

| Structure | Diameter | Nominal Thick | Min. thick | Nominal Diameter | Allowance | 20 ℃ | |

| mm² | No./mm | mm | mm | mm | mm | mm | Ω/KM |

| 0.2 | 12/0.15 | 0.60 | 0.6 | 0.44 | 1.80 | ±0.10 | 93.0 |

| 0.3 | 17/0.15 | 0.70 | 0.6 | 0.44 | 1.90 | ±0.10 | 64.4 |

| 0.4 | 23/0.15 | 0.80 | 0.7 | 0.53 | 2.20 | ±0.10 | 49.6 |

| 0.5 | 28/0.15 | 0.95 | 0.7 | 0.53 | 2.35 | ±0.15 | 40.1 |

| 0.75 | 42/0.15 | 1.15 | 0.7 | 0.53 | 2.55 | ±0.15 | 26.7 |

| 1.0 | 32/0.20 | 1.34 | 0.7 | 0.53 | 2.75 | ±0.15 | 20.0 |

| 1.25 | 40/0.20 | 1.50 | 0.7 | 0.53 | 2.90 | ±0.15 | 15.9 |

| 1.5 | 30/0.25 | 1.60 | 0.7 | 0.53 | 3.00 | ±0.15 | 13.7 |

| 2.0 | 41/0.25 | 1.90 | 0.7 | 0.53 | 3.30 | ±0.15 | 9.9 |

| 2.5 | 49/0.25 | 2.00 | 0.8 | 0.62 | 3.60 | ±0.20 | 8.21 |

| 4.0 | 56/0.30 | 2.70 | 0.8 | 0.62 | 4.30 | ±0.20 | 5.09 |

| 6.0 | 84/0.30 | 3.30 | 0.8 | 0.62 | 4.90 | ±0.20 | 3.39 |

| 10 | 84/0.40 | 4.60 | 1.0 | 0.8 | 6.60 | ±0.25 | 1.95 |

| 16 | 126/0.40 | 5.80 | 1.0 | 0.8 | 7.80 | ±0.25 | 1.24 |

| 25 | 196/0.40 | 7.30 | 1.0 | 0.8 | 9.30 | ±0.30 | 0.795 |

Links:https://globefindpro.com/products/89101.html

-

Fuel Consumption Flow Meter

Fuel Consumption Flow Meter

-

Oval Gear Flow Meter

Oval Gear Flow Meter

-

UL3642 Silicone Rubber Insulated Braided Jacket Lead Wire for Wind Power Generator Motor

UL3642 Silicone Rubber Insulated Braided Jacket Lead Wire for Wind Power Generator Motor

-

Turbine Flow Meter

Turbine Flow Meter

-

Silicone Rubber Insulation Wire (SIF-THT/SIE-THT)

Silicone Rubber Insulation Wire (SIF-THT/SIE-THT)

-

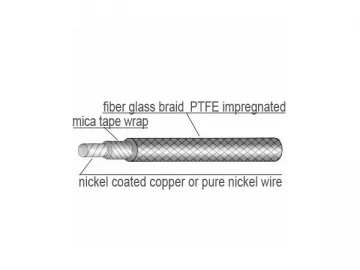

AFP-300/500V High Temperature Leading Wire

AFP-300/500V High Temperature Leading Wire

-

UL3640 Silicone Rubber Insulated Braided Jacket Lead Wire for Wind Power Generator Motor

UL3640 Silicone Rubber Insulated Braided Jacket Lead Wire for Wind Power Generator Motor

-

Electromagnetic Flow Meter

Electromagnetic Flow Meter

-

Roots Flowmeter

Roots Flowmeter

-

Portable Short Circuit Earthing Wire (DTRJ-I/DTRJ-II)

Portable Short Circuit Earthing Wire (DTRJ-I/DTRJ-II)

-

UL3643 Silicone Rubber Insulated Braided Jacket Lead Wire for Wind Power Generator Motor

UL3643 Silicone Rubber Insulated Braided Jacket Lead Wire for Wind Power Generator Motor

-

AMP-600V High Temperature Leading Wire

AMP-600V High Temperature Leading Wire