Auto Broiler Pan Feeding System

AutoBroiler Pan Feeding System

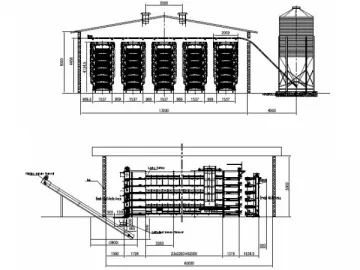

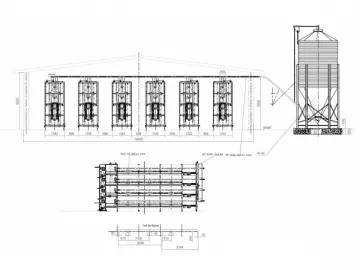

The auto broilerpan feeding system is mainly composed of silo, drive motor, delivery system,feed sensor, hopper, feed pan, hanging system, feed transportation vehicle,etc.

1. Silo

Features

1. The hot galvanized undulated sheets reduce temperaturefluctuations inside the silo.

2. The standard ladder with protection barrier ensuressafety and reliability.

3. The hopper has three different angles for differentmaterials, including 45°, 60° and 67°.

4. The silofeatures easy operation and excellent feed flow.

Specifications

|

| Volume | Fill Height | ||

| Model | Hopper | m³ | Ton | m |

| Diameter: 2.10m | ||||

| 702 | 60° | 8.7 | 5.7 | 4.56 |

| 703 | 60° | 11.6 | 7.5 | 5.37 |

| 704 | 60° | 14.5 | 9.4 | 6.18 |

| 705 | 60° | 17.4 | 11.1 | 7.00 |

| 706 | 60° | 20.3 | 13.2 | 7.81 |

| Diameter: 2.75m | ||||

| 902 | 60° | 15.8 | 10.3 | 5.26 |

| 903 | 60° | 20.6 | 13.4 | 6.07 |

| 904 | 60° | 25.0 | 16.5 | 6.88 |

| 905 | 60° | 30.2 | 19.6 | 7.70 |

| 906 | 60° | 35.0 | 22.8 | 8.51 |

| 907 | 60° | 39.8 | 25.9 | 9.32 |

| Diameter: 3.15m | ||||

| 1052 | 60° | 23.4 | 15.2 | 5.79 |

| 1053 | 60° | 30.0 | 19.5 | 6.60 |

| 1054 | 60° | 36.6 | 23.8 | 7.42 |

Note: Capacity in tons isbased on a specific weight of 0.65 kg/dm³.

2. FeedTransportation Vehicle

Features

1. The feedtransportation vehicle is special designed for transportation of feeds.

2. During thetransportation, feeds are sealed inside the tank, thus save the cost of packingand avoiding loss and pollution.

3. It featureseasy operation and maintenance, and the height, distance and angle of dischargecan be adjusted on request.

4. With separate containers,three types of materials can be transported each time.

Specifications

| Model | Volume (m³) | Dim of tank (LxWxH in mm) | Overall dim (LxWxH in mm) | No of container | Power (kw) | Max discharge height (m) |

| SSC4T | 7.5 | 3200x2110x1810 | 3900x2110x2500 | 2 | 11 | 6 |

| SSC6T | 11 | 4600x2110x1810 | 5300x2110x2500 | 2 | 13.6 | 7 |

| SSC10T | 16 | 6600x2110x1810 | 7300x2110x2500 | 3 | 14.6 | 7 |

| SSC15T | 25 | 7800x2250x1900 | 8500x2250x2600 | 4 | 16.1 | 8 |

3. Feed Delivery System

Content: Hopper;delivery pipe and auger, feed pan, feed sensor, drive motor, hang system, anti-roost piece.

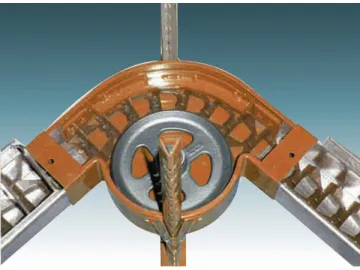

Delivery pipe and auger

With four different sizes, the deliverycapacity ranges from 15Pound (app. 6.8Kgs) /min to 220Pound (99.8Kgs) /min. Thepipe material is PVC or galvanized steel.

Feed Pan for Boiler

Features

1. V-pan platedesign can reduce feed storage on bottom, so that birds can always have freshfeed. The design can also prevent birds from staying too long on the plate.

2. The edge ofpan plate tilts towards the center, which can avoid waste of food.

3. The smoothedge can prevent the craw of birds from hurting and make sure safety andcomfort feeding.

4. The pan platecan be disassembled on the ground, working specially as a pan for 0-7 day oldchickens.

5. The typical 05feed pan has six feed levels, and can be manually or automatically adjusted.Other types have thirteen levels to adjust.

6. The slideshutter can be completely open or completely close, and can adjust feed amount.

7. The typical 05feed pan can be adjusted from outside, which brings more convenience andensures fast and accurate feeding.

8. The assembledpan can be fixed or swings on the pipe.

Feed sensor

Features

1. The feed sensor is installed in the feed pan, coming with the NO(normally open contact) function.

2. When lack of feed, the motor will start and deliver feeds. In addition, whenthe pans are full, the motor will stop (used in the main feed line).

3. It can also be fit at the bottom of hopper, coming with the NC (normallyopen contact) function, which is just opposite with the NO function.

As a China autobroiler pan feeding system supplier, Hylenoffers a broad range of products that includes belt laying battery, discharrow, straw pellet feed mill, disc blade, harvesting machine, and others.

Links:https://globefindpro.com/products/93550.html