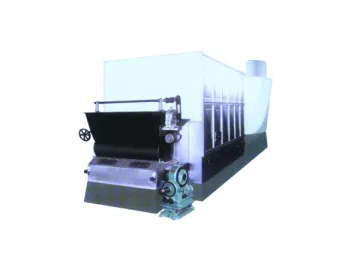

Single Spiral Dehydrator

SingleSpiral Dehydrator

Features

The singlespiral dehydrator adopts direct pressurizing method to dehydrate wetmaterials. It can be widely used inchemical industry, light industry, food industry and other industries. Forexample, this dehydrator is applicable to the dehydration and juicing processesof materials containing coarse fiber such as maize germ, maize fiber and yamslag in starch industry. The dehydrated materials can directly enter the nextprocedure for further drying, thus reducing the energy consumption of thedrying equipment.

As this piece of equipmentcan also recycle the starch residual water after squeezing fiber, the washingloss is reduced and starch recovery rate is increased, thereby improving theproduction environment and enhancing the economic benefit of the byproduct.

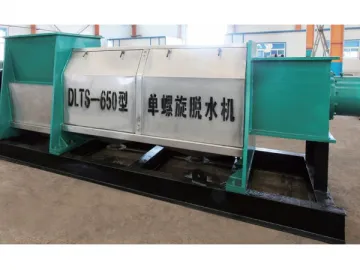

The single spiral dehydrator is of various specifications, ranging from type250 to type 650. It has assimilated advantages of the similar product made in China or other countries, and our maintechnologies are leading in China.

Specifications of Single SpiralDehydrator

| Model | Production Capacity(kg/h) | Incoming Water Content (%) | Outgoing Water Content (%) | Size(L*W*H mm) | Adaptive Power(KW) | Main Shaft Speed(rpm) | ||||||

|

| Fiber | Germ | Fiber | Germ | Fiber | Germ | Fiber | Germ | Fiber | Germ | Fiber | Germ |

| HLD250 | - | 500-800 | 85-90 | 75 | 60-65 | 55-60 | - | 3482×923×1004 | - | 7.5 | - | 17.6 |

| HLD350 | 3000-5000 | 800-1500 | 85-90 | 75 | 60-65 | 55-60 | 4050×900×1600 | 4050×900×1600 | 11 | 11 | 16.6 | 18 |

| HLD400 | 5000-6000 | - | 85-90 | 75 | 60-65 | 55-60 | 4658×1333×1280 | - | 18.5 | - | 13.5 | - |

| HLD500 | 5000-7000 | 1500-2000 | 85-90 | 75 | 60-65 | 55-60 | 5450×1630×1570 | 5260×1630×1570 | 22 | 18.5 | 12 | 15 |

| HLD550 | 7000-12000 | 2000-2500 | 85-90 | 75 | 60-65 | 55-60 | 5735×1280×1690 | 5615×1280×1690 | 30 | 22 | 12 | 15 |

| HLD650 | 12000-15000 | - | 85-90 | 75 | 60-65 | 55-60 | 5715×1540×1936 | - | 45 | - | 10 | - |

Links:https://globefindpro.com/products/93586.html