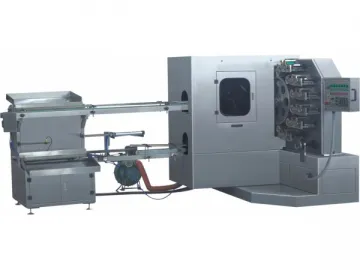

Vacuum Forming Machine

Vacuum Forming Machine

Model: ZH50-68/90S

Applications

The vacuum forming machine is used for PVC, PS, foamite PSP, PP, PET, environbiology degradative PP, etc. Itmakes all kinds of thin and open containers including a variety of disposablelunch boxes, fast food plates, instant noodle bowls, western food boxes, innerlinings of food packing, ice cream cups, candy boxes, etc. It is widely usedfor medicine, toy, journal, textile, light industry, agriculture and so on.

Technical Specifications of the VacuumForming Machine

| Sheet Material(mm) | PVC, PS, PET, PP | Foamite PSP |

| Width 500-680 Thickness 0.1-1.2 | Width 500-680 Thickness 1-3.5 | |

| Feeding Sheet Length (mm) | 600-950 adjustable | |

| Max. Mold Depth (mm) | Female mold 200 /Male mold 200 | |

| Speed (mold/min) | 3-8 times/min | |

| Total Power | AC380/220V 51kw (Max) | |

| Air Consumptions | ≧ 1.5M3 /mim (External air supply) | |

| Working Pressure | ≧ 0.6Mpa | |

| Overall Dimensions(mm) | 7500×2000×2250 | |

| Weight(kg) | 3500 kg | |

Features

1. The vacuum forming machine is a multi-station automatic machine,achieving continuous automatic procedures like feeding, forming, demolding, and cutting andstacking. The PLC control system makes the machine work more reliably.

2. It uses a double chain conveyor to make the feedingprocess stable and reliable. The width and length of required sheet can beadjusted accurately. It is fit for all kinds of molds (large depth) which canbe changed easily and reduce wasting.

3. The vacuum forming machine has a heating system with upper and lower heatersthat use infrared ray. The divisional temperature control system makes theheating process energy-saving and well-distributed.

4. The quenching system and water mist system are used to make the molds workcontinuously without a water-cooled system. It is especially used for non-metalmold.

5. The vacuum forming machine is equipped with a dual-shaft material loosingdevice, section-cutting system and stacking device to improve productiveefficiency.

Configuration List

| Inner Configuration Description | No. | Name | Brand | Place | Note |

| 1 | Vacuum Pump | Busch | German | Efficiency: 100 m3 /h | |

| 2 | Relay | OMRON | Japan | Model: MY2NJ | |

| 3 | PLC Computer | Siemens | German | Model: K-TP178(5.7 ") | |

| 4 | AC Contactor | Schneider | France | ||

| 5 | Approach Switch | Patelec | China | ||

| 6 | Transducer | OMRON | Japan | ||

| 7 | Temperature Controller | OMRON | Japan | ||

| 8 | Spray | Hang Tai | Taiwan | ||

| 9 | Electromagnetic Valve | 3/8Taiwan Gold Vessel, 1/2Japan SMC | |||

| 10 | Cylinder | Adopts American Piker rubber ring (Heng Yi) | |||

| 11 | Heating System | 120 blocks infrared porcelain heating (Sino-foreign JV) imported heating fuse | |||

| 12 | Temperature System | 60 groups solid state no grade temperature adjusting system, with stable temperature, long service life and not easily damaged | |||

As a major vacuum forming machine manufacturerand supplier based in China, our company also provides cup lid formingmachine, single layer plastic sheet extrusion machine, six color offsetprinting machine, flute laminating machine, and more.

Links:https://globefindpro.com/products/93651.html

-

Multifunctional Thermoforming Machine

Multifunctional Thermoforming Machine

-

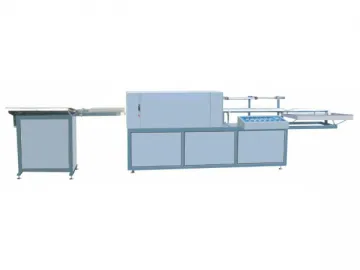

Cup Lid Forming Machine

Cup Lid Forming Machine

-

CK-410SS Roller POS Cash Drawer

CK-410SS Roller POS Cash Drawer

-

Plastic Cup Printing Machine

Plastic Cup Printing Machine

-

Horizontal Plastic Sheet Extruder

Horizontal Plastic Sheet Extruder

-

Double Layer Flat Sling

Double Layer Flat Sling

-

Plastic Cup Curling Machine

Plastic Cup Curling Machine

-

MK-350 Roller POS Cash Drawer

MK-350 Roller POS Cash Drawer

-

Cardboard Laminating Machine

Cardboard Laminating Machine

-

Cup Stacking Machine

Cup Stacking Machine

-

SK-480 Slide POS Cash Drawer

SK-480 Slide POS Cash Drawer

-

Single Layer Plastic Sheet Extrusion Machine

Single Layer Plastic Sheet Extrusion Machine