High Shear Emulsifying Mixer

High Shear EmulsifyingMixer

Features of High ShearEmulsifying Mixer

1. The high shear emulsifying mixer is designed with a largescale of heating area, to ensure high thermal efficiency and well-distributedheating and cooling effect.

2. It is easy to operate and clean, as it has a veryuser-friendly construction. The inner part of the emulsifying mixer is mirrorpolished (Ra≦0.4um). Each inlet and outletpipe, and the welding seam between the tank bottom and tank body are all in arcshaped, so they are easy for cleaning.

3. Inaddition, the high shear emulsifying mixer integrates multi-functions such asmixing, emulsifying, homogenizing, dissolving, smashing, and more. To getemulsion, the emulsifying head casts the materials around the rotor to thestator at high speed; then with the gears of the stator, the materials aresheared, crashed and smashed between the rotor and the stator to be emulsified.

Applications

The highshear emulsifying mixer is used for the sugar melting and powdering ofreconstituted milk, for the melting and stirring of beverage additives, as wellas the processing of other seasonings.

Technical Specifications of the High ShearEmulsifying Mixer

|

As a manufacturer of highshear emulsifying mixer in China, YINJI Company also supplies liquid deaerator,spray tunnel sterilizing machine, cream separator, and yoghurt tubularsterilizer, among others.

Links:https://globefindpro.com/products/93874.html

-

27" Intel® GM45 LCD Industrial Panel PC

27" Intel® GM45 LCD Industrial Panel PC

-

Qseven Spec Intel Atom Module

Qseven Spec Intel Atom Module

-

Emulsifying Powder Dissolving Machine

Emulsifying Powder Dissolving Machine

-

Video Storage Server

Video Storage Server

-

Intel Dual Core Atom Fanless Slim Media PC

Intel Dual Core Atom Fanless Slim Media PC

-

Intel Atom D525 12.1" Touch Panel Industrial PC

Intel Atom D525 12.1" Touch Panel Industrial PC

-

Yoghurt Fermenting Tank

Yoghurt Fermenting Tank

-

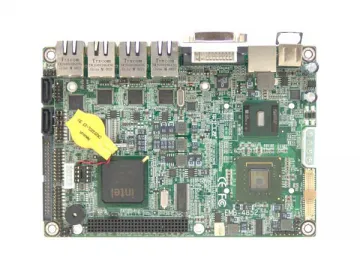

Intel Atom EPIC Fanless Embedded Motherboard

Intel Atom EPIC Fanless Embedded Motherboard

-

4U Rackmount Chassis

4U Rackmount Chassis

-

Ice Cream Aging Tank

Ice Cream Aging Tank

-

Intel® Core™ I7 OPS Module

Intel® Core™ I7 OPS Module

-

Powder Mixing Machine

Powder Mixing Machine