Data Logger of Pipe Welding Machine

Data Logger of Pipe Welding Machine

Main Functions

WPR1000 is matched with a PE pipebutt welding machine and its main functions are as follows:

1. Input or choose the preset welding parameters through the keyboard anddisplay interface.

2. Guide operators to complete the whole welding process.

3. Monitor all related welding parameters during the entire welding process.

4. Form and save the original records of various parameters during the weldingprocess.

Technical Parameters of the Data Logger of Pipe Welding Machine

| Overall size | 350×200×150 mm |

| Weight | 6.5Kg |

| Input voltage | 100~240VAC |

| Input frequency | 50Hz / 60Hz |

| Power | 24W |

| Stored records | 2000 welding points |

| User’s interface | USB口 |

| Protection grade | IP54 |

Structure

1 —Printer 2—Display Screen 3 —Keyboard 4 —PC Communication Port

5 —USB Connector 6 —Welding PhaseIndicator Lamp

1 —On/Off Power Switch 2 —Sensor of Ambient Temperature 3 —Nameplate

4 —Power Wire 5 —Sensor Input Socket

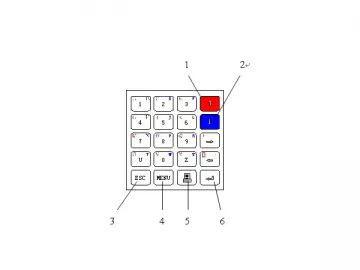

1 —Red Multifunction Key 2 —Blue Multifunction Key 3—Delete Key

4 —Menu Key 5 —Print Key 6 —OK (Enter) Key

Recording Paper Print Sample

We are a pipe welding machine manufacturer andsupplier based in China.We provide a vast range of products, including our data logger of pipe weldingmachine, plastic pipe welding machine, pipe cutting saw, pipe fusion machine,butt welding machine, electrofusion machine, and muchmore.

Links:https://globefindpro.com/products/94209.html