SHD630 Pipe Fusion Machine

SHD630 Pipe Fusion Machine

Features

1. The pipe fusion machine consists of a basic frame, hydraulic unit, planing tool, heating plate, support for planing tool and heating plate, and optional parts.

2. It has a removable PTFE coated heating plate with highly accurate temperature control system.

3. The pipe fusion machine is made of lightweight and high strength material. It is specially designed with a clamp opening angle of 45°.

4. Its low starting pressure ensures the reliable welding quality of small pipes.

5. It is an electric planing tool a with safety limit switch.

6. Changeable welding position enables the pipe fusion machine to weld various fittings more easily.

7. The pipe fusion machine offers a separate two-channel timer that records time in soaking and cooling phases.

8. The high accurate and shockproof pressure meter indicates clearer readings.

Applications

The pipe fusion machine is used for butt welding of plastic pipes and/or fittings made of PE, PP, and PVDF in a ditch at the worksite or the workshop.

Optional Parts

1. Stub end device for short flange stub

2. Crane

3. Data logger

Technical Parameters of the SHD630 Pipe Fusion Machine

Model | SHD630 | |

Pipe size(mm) | 315, 355, 400, 450, 500, 560, 630 | |

Heating plate max. temp . | 270 ℃ | |

Temp. deviation in surface(170~250℃ ) | < ±7℃ | |

Pressure adjustable ranges | 0-6.3Mpa | |

Working voltage | 380V, 50Hz | |

| Heating plate power | 9.35KW | |

Planing tool power | 1.5KW | |

Hydraulic unit power | 1.5KW | |

Total power | 12.35KW | |

Weight | 780Kg | |

Packing | Cases | 4 Plywood Cases |

Volume | 4.43CBM | |

As a professional pipe fusion machine manufacturer and supplier based in China, Shengda provides a wide array of products that includes our saddle pipe fusion machine, butt welding machine, electrofusion machine, plastic pipe welding machine, pipe fittings welding machine, pipe cutting saw, and more.

Links:https://globefindpro.com/products/94261.html

-

E11 E16 LED Ceiling Lamp

E11 E16 LED Ceiling Lamp

-

T3 2U Energy Saving Light Bulb

T3 2U Energy Saving Light Bulb

-

40W 54W LED Ceiling Lamp

40W 54W LED Ceiling Lamp

-

T5 Lotus Energy Saving Bulb

T5 Lotus Energy Saving Bulb

-

32-83W LED Ceiling Lamp

32-83W LED Ceiling Lamp

-

SHT160 Drainage Welding Machine

SHT160 Drainage Welding Machine

-

T8 Fluorescent Tube Light

T8 Fluorescent Tube Light

-

T5 Spiral Energy Saving Bulb

T5 Spiral Energy Saving Bulb

-

Pipe Fittings

Pipe Fittings

-

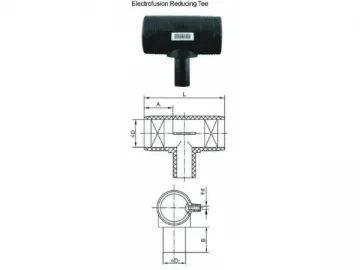

Electro-fusion Fittings

Electro-fusion Fittings

-

T2 Spiral Energy Saving Bulb

T2 Spiral Energy Saving Bulb

-

2-Wire LED Rope Light

2-Wire LED Rope Light