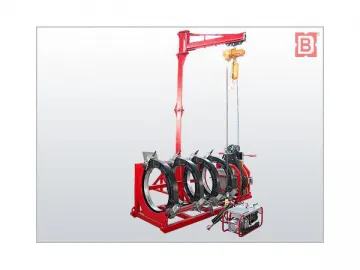

SHT315 Drainage Welding Machine

SHT315 DrainageWelding Machine

Features

1. The drainage weldingmachine has a removable PTFE coated heating plate with a highly accuratetemperature control system.

2. The electrical planing tool with safety limitswitch enables it to start only when it is locked in the operationposition.

3. The spring manometer provides correct welding pressure.

4. The drainage weldingmachine has a pivoting planing tool and heating platefor convenience when placing and removing.

5. The drainage welding machine has a mechanical lock to maintain weldingpressure.

Applications

The drainage welding machine is used for butt weldingof plastic pipes and/or fittings made of PE, PP, and PVDF in a ditch at theworksite or the workshop. It is also used to install drainage systems in buildings and has speciallydesigned clamps according to the features in the structure and dimensions offitting in the drainage system.

Optional Parts

1. Stub end device for short flange stub

2. Data logger

Technical Parameters of the SHT315 DrainageWelding Machine

| Model | SHT315 |

| Pipe size(mm) | 110,160,180,200,225,250,280,315 |

| Application | Pipe with pipe of fittings; fitting with fittings |

| Heating plate max. temp. | 260℃ |

| Temp. deviation in surface(170~250℃) | <±5℃ |

| Working voltage | 220V/240V, 50Hz |

| Planing tool power | 3.5KW |

| Hydraulic unit power | 1.1KW |

| Total power | 4.6KW |

| Weight | 250Kg (Doesn’t include optional parts) |

Our company is a professional drainage welding machine manufacturer andsupplier based in China.We specialize in the production of our plastic pipe welding machine, pipefittings welding machine, pipe fusion machine, electrofusion machine, pipe cutting saw, and butt welding machine.

Links:https://globefindpro.com/products/94271.html

-

T4 2U Energy Saving Bulb

T4 2U Energy Saving Bulb

-

T4 4U Energy Saving Bulb

T4 4U Energy Saving Bulb

-

PC Vacuum Forming

PC Vacuum Forming

-

Vacuum Forming Plastic Machine Casing

Vacuum Forming Plastic Machine Casing

-

T3 Energy Saving Light Bulb

T3 Energy Saving Light Bulb

-

T5 68*58mm Fluorescent Tube Light

T5 68*58mm Fluorescent Tube Light

-

SHD800 Pipe Fusion Machine

SHD800 Pipe Fusion Machine

-

SHT160 Drainage Welding Machine

SHT160 Drainage Welding Machine

-

32-83W LED Ceiling Lamp

32-83W LED Ceiling Lamp

-

T5 Lotus Energy Saving Bulb

T5 Lotus Energy Saving Bulb

-

40W 54W LED Ceiling Lamp

40W 54W LED Ceiling Lamp

-

T3 2U Energy Saving Light Bulb

T3 2U Energy Saving Light Bulb