Bulk Cement Semi Trailer

Bulk Cement Semi Trailer

Features and Applications of Bulk Cement Semi Trailer

1. Bulk cement semi trailer is also known as powder particle materialtrailer. It is made up of a special-purpose automotive chassis, bulk cementtank body, automatic discharging device and other parts.

2. Both the ferrous & nonferrous metal (stainless steel & aluminum)tank body is designed in compliance with GB18564-2001. It is highlycorrosion-resistant.

3. Tanker series include LPG Tank Semi-trailer, Powder Cement TransportSemi-trailer, and Milk Tank Semi-trailer, etc.

4. Our bulk cement semi trailer is quite suitable for the bulk transportationof fly ash, cement, lime powder, mineral powder and other powdered materialswith a diameter less than 0.1mm. It is mainly used in cement plants, cementwarehouses, and large-size construction sites, etc. By using it, the need forlarge quantities of packaging materials and discharging work is eliminated.

5. Moreover, the semi trailer can be connected to our tractor head.

Some Informationabout our company

As a professional bulk cement semi trailermanufacturer in China, we have the capacity to offer individualized services for ourcustomers.

Due to the high production capacity and outstanding performance, our tankertrucks and other heavy-duty trucks are now quite popular among our customers inVietnam, Myanmar, Malaysia, Peru, Cuba, Chad, Sudan, Egypt, Ghana, Nigeria, South Africa, Ethiopia,Angola, Algeria, Ukraine, Russia, and more.

If you are interested in our products, please feel free to contact us.

Technical Specification for Bulk Cement Trailer

1. Main Equipment of Bulk CementSemi Trailer

| No. | Name | Quantity/Unit | Model | |

| 1 | JOST kingpin | 1 | KZ1012/3.5" | |

| 2 | Landing leg | 1 set | JOST D200T | |

| 3 | Steel spring 10 piece/90*13 | 6 | FUYUAN | |

| 4 | Mechanic suspension of three axle | 1 set | FUWA /axle 1310mm | |

| 5 | Axle | 3 | SAF/KII KERZM12742, 2 axle have ABS | |

| 6 | Rim | 12 | ZHENGXING/8.50-20 | |

| 7 | Tire | 12 | Jiatong/12.00R20 | |

| 8 | Electric system | Bunch Lamps | 1 set | Entire airproof bunch lamps |

| seven core socket | 1 | BAOWEI | ||

| 9 | Braking system | Emergency relay valve | 1 | HALDEX |

| Air reservoir | 2 | 40L | ||

| Double braking chamber | 4 | 30/30 | ||

| Single braking chamber | 2 | 30 | ||

| Handle joint | 1/1 | ISO Standard joint | ||

| Handle valve | 1 | Pneumatic | ||

| ABS | 1 | WABCO | ||

| 10 | Tire bracket | 2 |

| |

| 11 | Tool box | 1 | 1500*540*620 | |

2. MainSpecification of Bulk Cement Semi Trailer

| No. | Specification | Numerical Value |

| 1 | Outside dimension(L×W×H)(mm) | 13000*2500*4000 |

| 2 | Wheelbase (mm) | 8110 1310 1310 |

| 3 | Front/rear suspension | /820 |

| 4 | Rated Payload (kg) | 26500 |

| 5 | Vehicle total weight(kg) | Approx.13300 |

| 6 | G.V.W (kg) | Approx.39800 |

3. Main Materialsand Manufacturing Technology of Bulk Cement Semi Trailer

| No. | Main Components | Spare Parts | Standard | Material | Main manufacture Technology |

| 1 | Raw material of vehicle |

|

|

| Using technology (sand blasting and pre-besmear primer) to deal with the surface of raw material |

| 2 | The girder of vehicle frame | Upper & lower wing-plate (mm) | 14/14 | 16Mn | Using hidden arc welding to deal with the girder |

| Belly-plate (mm) | 6 | 16Mn | |||

| Module height of the girder | 450 |

| |||

| 3 | The group welding of the vehicle |

|

|

| Welded by CO2 gas protection welding |

| 4 | Welding line of the vehicle |

|

|

| Using second time sand blasting |

| 5 | Painting system |

|

| Acrylic acid modify alkyd paint | Using technology (painting and roast). Painting color: yellow |

Technical Specification of Cement Tank Body

1. Main Specification of CementTank Body

| No. | Specification | Numerical Value |

| 1 | Outside Dimension(L×W×H)(mm) | 11950×2500×3280 |

| 2 | The tank effective volume (m3) | 55 |

| 3 | Rated volume (m3) | 55 |

| 4 | Manhole and ventilation valve | 2 |

| 5 | Pipeline system | 3″ |

| 6 | Ladder and walking platform | 1 |

2. Main Materialsand Manufacturing Technology of Cement Tank Body

| No. | Main components | Spare Parts | Standard | Material | Main Manufacture Technology |

| 1 | Tank body |

| 6 | Q235-A | Welded by CO2 gas protection welding, single face welding double face molding, molded by 6 m lapping machine |

| 2 | Tank head |

| 6 | Q235-A | Molded by automatic revolved machine |

| 3 | Air Compressor |

| DANDONG 10 M⒊ |

|

|

| 4 | Painting system |

|

| Acrylic acid modify alkyd paint | Using technology (painting and roast). |

Links:https://globefindpro.com/products/96645.html

-

Flatbed Trailer

Flatbed Trailer

-

Tank Semi Trailer

Tank Semi Trailer

-

Dump Semi Trailer

Dump Semi Trailer

-

Optional Modules: Alarm Input Module MAG1880;Alarm Output Module MAG1832;Telephone Module MAG1824;Remote Paging Module MAG1826;Periphery Control Modul

Optional Modules: Alarm Input Module MAG1880;Alarm Output Module MAG1832;Telephone Module MAG1824;Remote Paging Module MAG1826;Periphery Control Modul

-

Side Dump Truck

Side Dump Truck

-

Programmable Player MAG5366,Network PA System

Programmable Player MAG5366,Network PA System

-

Woodworking CNC Router NC-RS1325

Woodworking CNC Router NC-RS1325

-

Aluminum Coil (Aluminum Sheet Coil)

Aluminum Coil (Aluminum Sheet Coil)

-

Laser Engraving Machine (NC-E4060)

Laser Engraving Machine (NC-E4060)

-

Solution

Solution

-

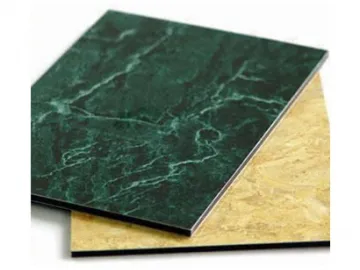

Granite / Wood Aluminium Composite Panel

Granite / Wood Aluminium Composite Panel

-

Advertising CNC Router NC-B3636

Advertising CNC Router NC-B3636