Injection Molding Machine

Precision Machinery, Injection Molding System  Molding Equipment Recommendations Rubber Molding Machine

Molding Equipment Recommendations Rubber Molding Machine

LSR Molding Machine, Liquid Silicone Rubber Molding Machine

Specifications

Injection Molding Machine

Specifications

Benefits The injection molding machine is equipped with an automatic feeding system, thus ensuring material weighing and cutting processes are not necessary. The specially designed mold runner easily injects raw materials into complicated mold cavities. The injected raw material’s quantity is controlled to effectively reduce the risk of rough edges. This machine is suitable for deep cavity and complicated mold. It uses different demolding mechanisms to reduce manual operation time.

Hisun provides injection molding machines in a variety of capacities, ranging from 50 to 3000 tons. We also offer customized injection molding machines to meet unique customer requirements.

LSR Molding Machine, Liquid Silicone Rubber Molding Machine

Specifications

| Capacity (tons) | 200 | 250 | 300 |

| Platen Size(mm) | 500*550 | 580*600 | 700*700 |

| Cylinder Bore (mm) | Ø355 | Ø460 | Ø560 |

| Stroke(mm) | 500 | 560 | 600 |

| Horsepower (HP) | 10 | 20 | 25 |

| Power(KW) | 20 | 28 | 32.5 |

| Injection Capacity (C.C) | 1600 | 3000 | 4500 |

| Mold Opening Method | Rise and Descend | Front Ejection | Push and Pull |

Injection Molding Machine

Specifications

| Capacity (tons) | 200 | 300 | 500 |

| Platen Size(mm) | 500*550 | 580*600 | 700*700 |

| Cylinder Bore (mm) | Ø355 | Ø460 | Ø560 |

| Stroke(mm) | 500 | 560 | 600 |

| Horsepower (HP) | 10 | 20 | 25 |

| Power(KW) | 20 | 28 | 32.5 |

| Injection Capacity (C.C) | 1600 | 3000 | 4500 |

| Mold Opening Method | Rise and Descend | Front Ejection | Push and Pull |

Scan QR to Read

Links:https://globefindpro.com/products/9730.html

Links:https://globefindpro.com/products/9730.html

Recommended Products

-

Partnership

Partnership

-

B10D Series Double-station Blow Molding Machine

B10D Series Double-station Blow Molding Machine

-

Fiber Opener

Fiber Opener

-

Presses We Offered

Presses We Offered

-

SZYT560 Fiber Opening and Filling Machine

SZYT560 Fiber Opening and Filling Machine

-

HSV Vacuum Press

HSV Vacuum Press

-

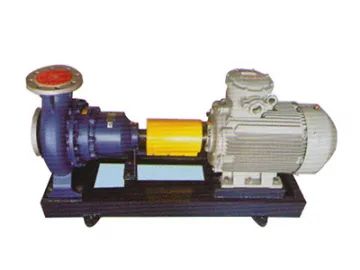

BA Series Centrifugal Pumps

BA Series Centrifugal Pumps

-

MCZ Series Magnetic Drive Pumps

MCZ Series Magnetic Drive Pumps

-

FMD Series Magnetic Drive Pumps

FMD Series Magnetic Drive Pumps

-

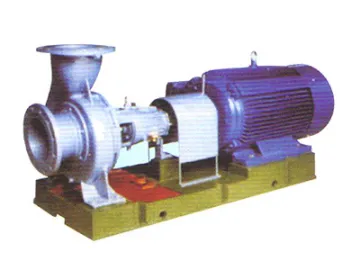

ZAO Series Centrifugal Pumps

ZAO Series Centrifugal Pumps

-

WIHF Series Centrifugal Pumps

WIHF Series Centrifugal Pumps

-

MDZA Series Magnetic Drive Pumps

MDZA Series Magnetic Drive Pumps

Hot Products