HSI Vacuum Press, 4 Post Press

Vacuum Chamber Press Features Vacuum Shroud and Hydraulic System Benefits The vacuum forming process ensures an excellent raw material fluidity and reduces the rate of bubble occurrence. Processing workpieces in the vacuum chamber also reduces heat dissipation, shortens the production time, and improves productivity. This vacuum press features a variety of demolding devices, ensuring it is suitable for a wide array of mold types. Specifications

| Capacity (tons) | 200 | 250 | 300 |

| Platen Size (mm) | 520*530 | 560*600 | 600*650 |

| Cylinder Bore (mm) | Ø355 | Ø400 | Ø450 |

| Stroke (mm) | 250 | 300 | 300 |

| Horsepower (HP) | 10 | 10 | 10 |

| Vacuum Pump Horsepower (HP) | 3 | 3 | 3 |

| High Speed (mm/sec) | 30 | 30 | 30 |

| Low Speed (mm/sec) | 1~3 | 1~3 | 1~3 |

| Weight (KG) | 9000 | 10000 | 12500 |

| Dimension (mm) | 3000*1800*2100 | 3300*1800*2100 | 3500*2000*2100 |

Scan QR to Read

Links:https://globefindpro.com/products/9749.html

Links:https://globefindpro.com/products/9749.html

Recommended Products

-

Stuffed Toy Filling Line

Stuffed Toy Filling Line

-

Machinery

Machinery

-

Toy Stuffing Machine

Toy Stuffing Machine

-

Vacuum Molding Press

Vacuum Molding Press

-

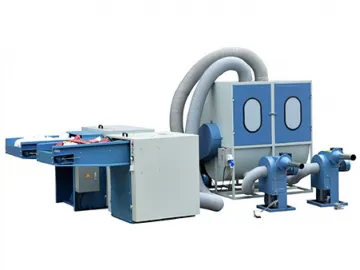

SZ300 Pillow and Cushion Filling Line (Fiber Opening, Foam Shredding, Mixing and Filling)

SZ300 Pillow and Cushion Filling Line (Fiber Opening, Foam Shredding, Mixing and Filling)

-

CQB Series Magnetic Drive Pumps

CQB Series Magnetic Drive Pumps

-

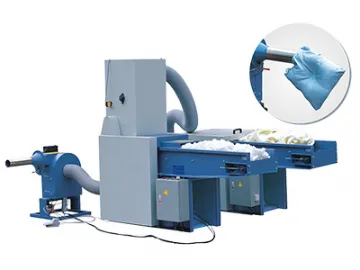

SZ120 Pillow and Cushion Filling Line

SZ120 Pillow and Cushion Filling Line

-

Bale Opener

Bale Opener

-

B20D Series Double-station Blow Molding Machine

B20D Series Double-station Blow Molding Machine

-

B25D Series Double-station Blow Molding Machine

B25D Series Double-station Blow Molding Machine

-

HSV Compression Molding Press

HSV Compression Molding Press

-

SZ150 Pillow and Cushion Filling System (Fiber Opening, Foam Shredding, Mixing and Filling)

SZ150 Pillow and Cushion Filling System (Fiber Opening, Foam Shredding, Mixing and Filling)

Hot Products