Tile Roll Forming Machine

Tile Roll Forming Machine, Tile Forming Machine

Tile Roll Forming Machine, Tile Forming Machine

:()

Different tile roof forming machines can producedifferent shapes of steel tile roof sheets in various thickness and colors.Steel tile roof sheets are the new substitutes for traditional clayey, concretetiles. They are popular because of their low cost, short building period, re-cycle use, and elegant appearance.

:()

Model Number: 27-741

Thickness: 0.35-0.65mm

Effective Width: 741mm

Feeding Width: 914mm,36inch

Roll Station: 14

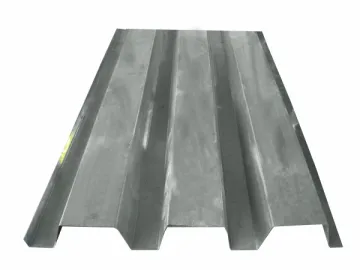

Drawingfor the YX27-741 Roof Tile Panel

| Type | Name | Effective Width | Feeding Width | Thickness |

| YX27-741 | Tile Roll Forming Machine | 741mm | 914mm/36inch | 0.35-0.65mm |

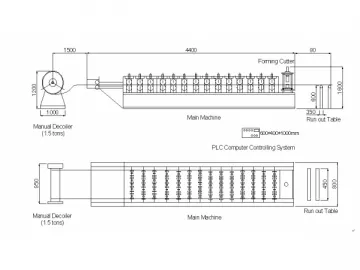

Producing Process Sketch

Constructionof the Roof Tile Panel

YX27-741Tile Forming Machine

MainAccessories

1. Main machine

2. Manual/hydraulic decoiler

3. Manual pre-cutting

4. Hydraulic system

5. PLC computer controlling system

6. Hydraulic press device withmold

7. Forming cutter

8. Run out table (3 units)

9. User’s manual in English

Features

Differenttile roof forming machines can produce different shapes of steeltile roof sheets in various thickness and colors. Steel tile roof sheets arethe new substitutes for traditional clayey, concrete tiles. They are popularbecause of their low cost, short building period,re-cycle use, and elegant appearance. They are used as the roof of villas,luxury houses, theatres, exhibition centers, etc.

Thecomplete tile roll forming machine line includes decoiler,main machine, computercontrolling system and run out tables. Our machines are equipped with acomputer controlling system. We simply program the pieces and length we need inthe computer and the tile forming machine produces it automatically. Themachines are easy to operate and running stable.

After-saleService

Links:https://globefindpro.com/products/98587.html

-

Hooklift Garbage Truck

Hooklift Garbage Truck

-

Steel Keel Processing Machine

Steel Keel Processing Machine

-

Steel Floor Roll Forming Machine

Steel Floor Roll Forming Machine

-

Keel Roll Forming Machine

Keel Roll Forming Machine

-

Floor Decking Roll Forming Machine

Floor Decking Roll Forming Machine

-

Bulk Cement Trailer

Bulk Cement Trailer

-

Steel Floor Decking Roll Forming Machine

Steel Floor Decking Roll Forming Machine

-

Bullerc 6X4 Terminal Tractor

Bullerc 6X4 Terminal Tractor

-

Guide Rail Machine

Guide Rail Machine

-

U Roll Forming Machine

U Roll Forming Machine

-

Keel Machine

Keel Machine

-

Stud Machine

Stud Machine