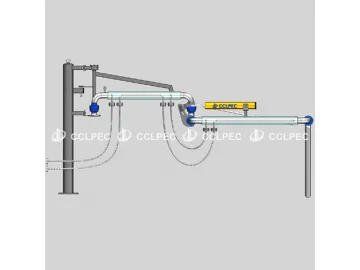

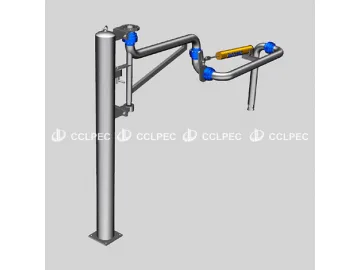

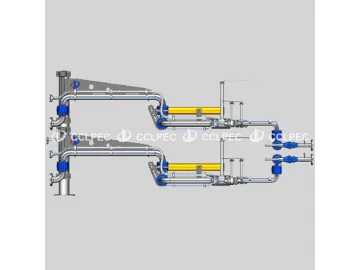

Top Loading Arm with Heat Tracing

The heat traced top loading arm is typically designed for loading and unloading of high viscosity medium that require heating to improve its fluidity. The heat tracing system is composed of heating unit and thermal insulation. Electrical heating unit or steam heating unit is selectable per your specific needs.

Scan QR to Read

Links:https://globefindpro.com/products/9918.html

Links:https://globefindpro.com/products/9918.html

Recommended Products

-

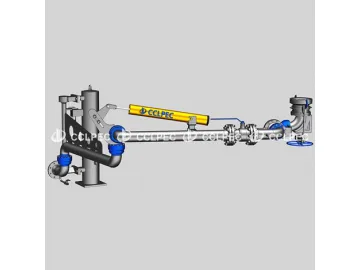

Bottom Loading Arm (Russian Type)

Bottom Loading Arm (Russian Type)

-

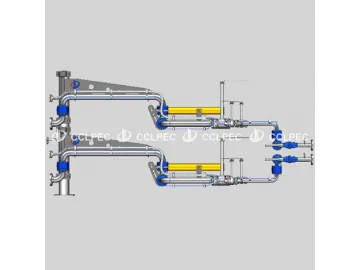

LNG Truck Loading Arm

LNG Truck Loading Arm

-

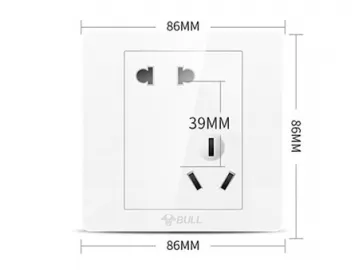

86-5 Electrical Socket

86-5 Electrical Socket

-

Extraction Arm

Extraction Arm

-

Benchtop Fume Hood

Benchtop Fume Hood

-

Manual Release Quick Release Mooring Hook

Manual Release Quick Release Mooring Hook

-

Quick Connect / Disconnect Coupler (QCDC)

Quick Connect / Disconnect Coupler (QCDC)

-

Dry Break Coupler

Dry Break Coupler

-

Top Loading Arm

Top Loading Arm

-

ACME Threaded Coupling

ACME Threaded Coupling

-

LNG Marine Loading Arm

LNG Marine Loading Arm

-

LNG ISO Tank Loading Arm

LNG ISO Tank Loading Arm