Pipe Flaring Belling Machine

PipeFlaring Belling Machine

Good Points of Pipe Flaring Belling Machine

1. Extruding machine uses full-auto pipe expander with drawing device andprogram interface.

2. Single operation is also available.

3. While expanding pipes, it will adopt a translation mode, which is bothsteady and correct without damaging pipe materials.

4. The machine applies electric heating type, and each oven is equipped with aheating core.

5. The shaping method adopts expanding-end shaping.

6. It is very convenient to choose expanding pipe type.

7. Strong technological adaptability, all the key electric control elements areimported.

Application ofPipe Flaring Belling Machine

The belling machine is suitable for the belling of PVC solid wall pipe, PVC double-wall corrugated pipe and PE double-wallcorrugated pipe.

The belling type: Flat type and R type.

Product range: Φ32-Φ800

Main TechnicalParameters of Pipe Flaring Belling Machine

| Model | FN110 | FN250 | FN450 | FN630 | FN800 |

| Belling Diameter | Φ32~Φ110 | Φ63~Φ250 | Φ160~Φ450 | Φ315~Φ630 | Φ630~Φ800 |

| Rated Hydraulic Pressure | 3 MPa | 3 MPa | 5 MPa | 5 MPa | 5 MPa |

| Compressed Air | 0.4 MPa | 0.4 MPa | 0.4 MPa | 0.4 MPa | 0.4 MPa |

| jwell. Total Power | 10Kw | 20Kw | 25Kw | 40Kw | 60Kw |

The connection of PVC pipe

| Connection | Application |

| Agglomerant connection | The connection of pipe and fitting is the suitable for small pipe. |

| Belling connection | The connection of PVC pipe, it also can connect with other material pipe. It is suitable for larger diameter pipe and buried pipe. |

| Flange connection | It is suitable for the connection of larger diameter pipe and fitting or other material pipe. |

| Screw thread connection | The connection of small PVC pipe and other material pipe, metal fitting, or water consuming equipment |

Note: The pipe over Φ160mm can not use agglomerantconnection.

The connection process of belling connection

1. Clean the outside and the inside of the inserting end with dishcloth.

2. Draw the depth label on the inserting end

3. Put the rubber ring into the notch of inserted end, and then wet andlubricate the rubber ring and inserting end.

4. Insert the right pipe to the rated depth, and then insert the feeler gaugeinto the clearance to check the connection.

Note:

Blow 100mm outerdiameter can insert with hand, over 100mm use the pulling device. Insert should along thelongitudinal of pipe, no outside knock

We have many years experience of making plasticextrusion machinery and plastic recycling machinery. It is enough for us tooffer excellent waste plastic recycling machine, plastic granulating & pelletizing line, plastic sheet production line, plasticprofile production line and other plastic extrusion machinery for you.

Links:https://globefindpro.com/products/101958.html

-

Knife Grinding Machine

Knife Grinding Machine

-

Fiber Film Agglomeration Machine

Fiber Film Agglomeration Machine

-

Plastic Crusher

Plastic Crusher

-

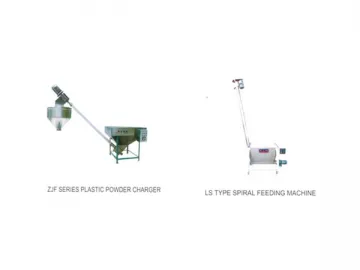

Plastic Auto Loading Machine

Plastic Auto Loading Machine

-

Bottle Label Remove Machine

Bottle Label Remove Machine

-

Hydraulic Baler

Hydraulic Baler

-

Wood Plastic Composite Sheet / Panel Production Line

Wood Plastic Composite Sheet / Panel Production Line

-

Plastic Shredder

Plastic Shredder

-

Plastic Compound Mixer

Plastic Compound Mixer

-

PPR Pipe Production Line

PPR Pipe Production Line

-

PU PVC Medicine Pipe Production Line

PU PVC Medicine Pipe Production Line

-

Men's socks

Men's socks