Atlas Copco Air Dryer FD

AtlasCopco Air Dryer FD

"Adsorption type desiccant industry benchmark"

Clean and dry compressed air: optimization busy production environment is veryimportant. Untreated compressed air contains moisture, haze and dust particles,such as air might damage the air system and the final product, so will causegreat risk.

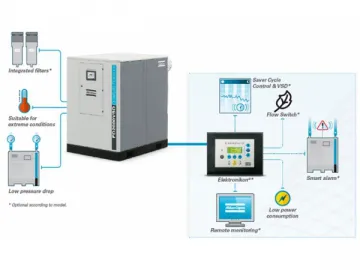

Atlas Copco air dryer FD integrates unique patented technology and special variousoptional units offering high energy efficiency, so it can offer you the clean,dry air needed, prolong the service life of your equipment and ensure thequality of the final product.

From the small workshop to fluctuations in temperature great environment, AtlasCopco air dryer FD provides good air treatment effect. FD air dryer because ofits small size, integrated modern design and perfect monitoring capabilities,can provide excellent advantage, and meet the most stringent requirements.

FD freeze-drying machine for use namely, easy to install and can makeproduction downtime is reduced to the minimum. Due to its tight integration designcan eliminate the extra needs, so absolutely installation costs can be reducedto the minimum.

FD air dryer design completely integrated and cover an area of an area small,thus saving covers an area of space and installation costs:

Installed in the electronic items within non-loss drain valve.

General only a roadside

Equipment air interface on the top (be) according to the model.

Integration OSD oil-water separator (optional parts).

Built-in DD and PD filter (optional parts).

Atlas Copco air dryer FD can eliminate moisture under the harshest conditions,except the compressed air and eliminate the system failure, production downtimeand expensive repair and maintenance work.

The Atlas Copco air dryer FD,by ensuring the lowest pressure drop and energy loss, provides the highestpossible efficiency. It saves you a lot of time and money in the wholeproduction process, which all thanks to its advanced technology.

FD 5-285 Air CooledType - 50 Hz

| Model | Outlet air flow PDP is 3°C/36°F | Pressure drop | Energy consumption | Max. working pressure | Compressed air connector |

| m³/min | bar | kW | bar | ||

| FD 5 | 0.36 | 0.09 | 0.2 | 14.5 (1) | R ¾ |

| FD 10 | 0.60 | 0.09 | 0.3 | 14.5 (1) | R ¾ |

| FD 15 | 0.90 | 0.20 | 0.3 | 14.5 (1) | R ¾ |

| FD 20 | 1.14 | 0.23 | 0.3 | 14.5 (1) | R ¾ |

| FD 25 | 1.44 | 0.24 | 0.4 | 14.5 (1) | R ¾ |

| FD 30 | 1.80 | 0.09 | 0.5 | 13 (1) | R1 |

| FD 35 | 2.10 | 0.11 | 0.5 | 13 (1) | R1 |

| FD 45 | 2.70 | 0.15 | 0.7 | 13 | R1 |

| FD 65 | 3.90 | 0.25 | 0.8 | 13 | R1 ½ |

| FD 95 | 5.71 | 0.25 | 0.8 | 13 | R1 ½ |

| FD 120 | 7.21 | 0.11 | 1.1 | 13 | R1 ½ |

| FD 150 | 9.01 | 0.15 | 1.3 | 13 | R1 ½ |

| FD 185 | 11.11 | 0.22 | 1.6 | 13 | R2 ½ |

| FD 220 | 13.22 | 0.12 | 1.8 | 13 | R2 ½ |

| FD 245 | 14.72 | 0.18 | 2.1 | 13 | R2 ½ |

| FD 285 | 17.12 | 0.22 | 2.4 | 13 | R2 ½ |

FD 5-285 Air CooledType - 60 Hz

| Model | Outlet air flow PDP: 4°C/39°F | Pressure drop | Energy consumption | Max. working pressure | Compressed air connector |

| m³/min | bar | kW | bar | ||

| FD 5 | 0.36 | 0.09 | 0.2 | 14.5 (1) | NPT ¾ |

| FD 10 | 0.60 | 0.09 | 0.3 | 14.5 (1) | NPT ¾ |

| FD 15 | 0.90 | 0.20 | 0.3 | 14.5 (1) | NPT ¾ |

| FD 20 | 1.14 | 0.23 | 0.3 | 14.5 (1) | NPT ¾ |

| FD 25 | 1.44 | 0.24 | 0.4 | 14.5 (1) | NPT ¾ |

| FD 30 | 1.80 | 0.09 | 0.5 | 13 (1) | NPT 1 |

| FD 35 | 2.10 | 0.11 | 0.5 | 13 (1) | NPT 1 |

| FD 45 | 2.70 | 0.15 | 0.8 | 13 | NPT 1 |

| FD 65 | 3.90 | 0.25 | 1.0 | 13 | NPT 1¼ |

| FD 95 | 5.71 | 0.25 | 1.0 | 13 | NPT 1½ |

| FD 120 | 7.21 | 0.11 | 1.2 | 13 | NPT 1½ |

| FD 150 | 8.41 | 0.15 | 1.6 | 13 | NPT 1½ |

| FD 185 | 10.21 | 0.22 | 2.0 | 13 | NPT 2½ |

| FD 220 | 13.22 | 0.12 | 2.2 | 13 | NPT 2½ |

| FD 245 | 13.82 | 0.18 | 2.3 | 13 | NPT 2½ |

| FD 285 | 17.12 | 0.22 | 2.4 | 13 | NPT 2½ |

Notes:

(1) : 20 bar (e) (290 psi) models are available.

The benchmark of 50 Hz: ambient air temperature: 25 ° C, 77F; inlet compressedair temperature: 35 ° C, 95 ° F; inlet pressure: 102 bar / 7 psig (e)

Benchmark conditions of 60Hz: environmental temperature 60 ° C, 100:38 ° F;inlet compressed air temperature: 38 °C, 100 F; inlet pressure: 102 psig / 7 bar(e)

Extreme conditions * :

environmental temperature: 46° C, 115 F; inlet compressed air temperature: 56 °C, 133F

* non-datum conditions on the dryer selection, please give Atlas Copcoconsultation.

Refrigerant type: FD 5-95: R134a; FD 120-285: R410a

Relevant energy-saving circulation FD freeze-drying machine of detailedinformation, please refer to the FD 120-285 independent sample.

FD 280-4000 air cooled and water cooled - 50 Hz

| Model | Air flow | Pressure drop | Consumption | Max. working pressure | Compressed air connector |

| m³/min | bar | kW | bar | ||

| FD 280 | 16.82 | 0.24 | 3.7 | 13 | R3 |

| FD 300(1) | 18.86 | 0.15 | 3.4 | 14.5 | R3 |

| FD 380(1) | 22.83 | 0.09 | 4.0 | 14.5 | R3 |

| FD 450(1) | 27.03 | 0.15 | 4.6 | 14.5 | R3 |

| FD 600 | 36.05 | 0.21 | 5.8 | 13 | DN100 |

| FD 750 VSD/FS | 45.06 | 0.29 | 5.1 | 13 | DN100 |

| FD 860 VSD/FS | 51.66 | 0.14 | 5.3 | 13 | DN150 |

| FD 1000 VSD/FS | 60.08 | 0.17 | 6.0 | 13 | DN150 |

| FD 1250 VSD/FS | 75.10 | 0.24 | 8.3 | 13 | DN200 |

| FD 1400 VSD/FS | 84.11 | 0.24 | 8.5 | 13 | DN200 |

| FD 1600 VSD/FS | 96.12 | 0.14 | 14.6 | 13 | DN200 |

| FD 2000 VSD/FS | 120.15 | 0.22 | 17.0 | 13 | DN200 |

| FD 2400 VSD(1)(2) | 144.18 | 0.23 | 18.0 | 13 | DN200 |

| FD 4000 VSD(1)(2) | 240.30 | 0.22 | 27.9 | 13 | DN250 |

FD 280-4000 aircooled and water cooled type - 60 Hz

| Model | Air flow | Pressure drop | Consumption | Max. working pressure | Compressed air connector |

| m³/min | bar | kW | bar | ||

| FD 280 | 16.82 | 0.24 | 3.7 | 13 | R3 |

| FD 300(1) | 18.86 | 0.15 | 3.4 | 14.5 | R3 |

| FD 380(1) | 22.83 | 0.09 | 4.0 | 14.5 | R3 |

| FD 600 | 36.05 | 0.21 | 5.8 | 13 | -4 |

| FD 750 VSD/FS | 45.06 | 0.29 | 5.1 | 13 | -4 |

| FD 860 VSD/FS | 51.66 | 0.14 | 5.3 | 13 | 6 |

| FD 1000 VSD/FS | 60.08 | 0.17 | 6.0 | 13 | 6 |

| FD 1250 VSD/FS | 75.10 | 0.24 | 8.3 | 13 | 6 |

| FD 1400 VSD/FS | 84.11 | 0.24 | 8.5 | 13 | 8 |

| FD 1600 VSD/FS | 96.12 | 0.14 | 14.6 | 13 | 8 |

| FD 2000 VSD/FS | 120.15 | 0.22 | 17.0 | 13 | 8 |

| FD 2400 VSD/FS(1)(2) | 144.18 | 0.23 | 18.0 | 13 | 8 |

| FD 4000 VSD/FS(1)(2) | 240.30 | 0.22 | 27.9 | 13 | 10 |

Links:https://globefindpro.com/products/103527.html

-

Atlas Copco Freeze Dryer FX 1-16

Atlas Copco Freeze Dryer FX 1-16

-

Atlas Copco Compressed Air Dryer

Atlas Copco Compressed Air Dryer

-

New Sail Fog Lamp, Chevrolet Sail 04'

New Sail Fog Lamp, Chevrolet Sail 04'

-

Oil Free Rotary Tooth Air Compressor

Oil Free Rotary Tooth Air Compressor

-

500KW Oil Injected Screw Air Compressor

500KW Oil Injected Screw Air Compressor

-

Atlas Copco Portable Air Compressor

Atlas Copco Portable Air Compressor

-

Audi Parts A6 Fog Lamp

Audi Parts A6 Fog Lamp

-

City Bus YTK6730G

City Bus YTK6730G

-

City Bus YTK6710G

City Bus YTK6710G

-

City Bus YTK6720G

City Bus YTK6720G

-

Automatic On-Line Cutting Machine

Automatic On-Line Cutting Machine

-

Dust Collector For Melting Furnace

Dust Collector For Melting Furnace