MFCCE Continuous Extrusion Machine

MFCCE Continuous Extrusion Machine

Our MFCCE range of continuous extrusion machine brings up atechnological revolution in copper and aluminum processing industry.

When raw materials are continuously fed into a rotary extrusion wheel with grooves,the material temperature is increased rapidly, due to powerful friction andextrusion force. After the temperature reaches recrystallization temperature, the materials are recrystallized. Thenthey flow into the extrusion die and finally, finished products are achieveddirectly.

Through changing the die,the continuous extrusion machine can be used for extrusion of copper flat wire, copper busbar, copper strips, copper rod,aluminum flat wire, aluminum round pipe, aluminum multi-holeflat pipe, and more. The extruded products are extensively used intransformers, electrical motors, high and low voltage electrical equipment,electric vehicles, and the evaporator and condenser of automotive, refrigeratorand air conditioner, etc.

Technical Advantages

1. Technical Process

The continuous extrusion machine can finish following steps at a stroke, fromfeed stock unwinding and straightening, through continuous extrusion, cooling,anti-oxidation, drying, and auto-metering, to final automatic rewinding.

2. Five Advantages over Traditional Extrusion Techniques

(1) Fewer steps and low investment

MFCCE continuous extrusion machine can finishextrusion processes at a stroke, without requirements for auxiliary equipmentlike annealing furnace, heater, pickling machine, and trimming machine, etc.Hence, Continuous Extrusion Machine is time saving and environmental friendly.

(2) Energy saving and no requirement for external heating equipment

During extrusion process, the feed stock is providedwith abundant heat source through friction and extrusion. This eliminates thedemand for annealing and additional heating, which saves energy resourcegreatly.

(3) Low loss and high passing rate

Continuous extrusion process requires no trimming steps, thus ensuring highmaterial utilization rate. Also, the continuous extrusion machine comes withhigh finished product qualification rate, 95% for copper products and 99% foraluminum products.

(4) Low labor force requirement and high automation

The whole extrusion line is intelligent controlled,and only 2 operators are required. As we have said before, the continuousextrusion line can be used for manufacturing different types of products atdifferent sizes. To change from one size to another is simply a case ofchanging the extrusion die. So easy to use!

This Continuous Extrusion Machine is an ideal solution for producing products atdifferent specifications, in medium and small quantity.

(5) Superior finished product quality

During continuous extrusion, the feed stock is givenquick temperature rise and then recrystallized. Thus,the internal defects of the feed stock are completely removed. Meanwhile, ourcontinuous extrusion machine is designed with high quality extrusion die, whichensures the precise size and quality sectional shape of finished products.

After extrusion, the feed material property is greatly improved. With increasedcompactness and uniform and compact crystalline grain, the material andfinished products come with low electrical resistivity and high electrical conductivity, without necessary for annealing. Also, theproduct quality is consistent.

Yajue is a China continuous extrusion machinemanufacturer, specializing in a great variety of large scale electricalequipment. Some of our popular products include automatic hydraulic drawingbench machinery, upward casting machine, horizontal winding machine, and more.As a result of their high quality and low prices, our products are sought afterby customers in many countries, such as United States, France,Germany, Russia, Ukraine,South Korea, Syria, amongothers. Located in Shanghai,we enjoy convenient air, land and sea transportation. Moreover we have easyaccess to abundant manpower and thus can produce high quality products atreduced costs. For more detailed information about us, please contact usdirectly or send an email to us.

Links:https://globefindpro.com/products/103541.html

-

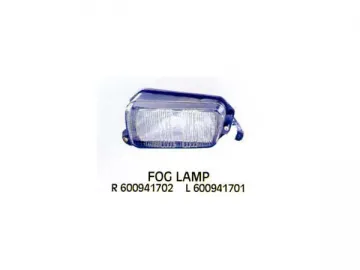

Volkswagen Fog Lamp

Volkswagen Fog Lamp

-

Atlas Copco Booster Air Compressor

Atlas Copco Booster Air Compressor

-

Atlas Copco Portable Lighting Machine

Atlas Copco Portable Lighting Machine

-

Honda Headlamp

Honda Headlamp

-

Aveo Sedan 07 Fog Lamp, Chevrolet Lova Sedan

Aveo Sedan 07 Fog Lamp, Chevrolet Lova Sedan

-

Audi Grille

Audi Grille

-

New Epica Fog Lamp, Chevrolet Epica 06'-07'

New Epica Fog Lamp, Chevrolet Epica 06'-07'

-

Atlas Copco Explosion Proof Air Compressor

Atlas Copco Explosion Proof Air Compressor

-

Atlas Copco Portable Air Compressor

Atlas Copco Portable Air Compressor

-

500KW Oil Injected Screw Air Compressor

500KW Oil Injected Screw Air Compressor

-

Oil Free Rotary Tooth Air Compressor

Oil Free Rotary Tooth Air Compressor

-

New Sail Fog Lamp, Chevrolet Sail 04'

New Sail Fog Lamp, Chevrolet Sail 04'