Hot Mold Method Centrifugal Casting Machine / Spinning Machine

Hot Mold Method Centrifugal Casting Machine / Spinning Machine

Description

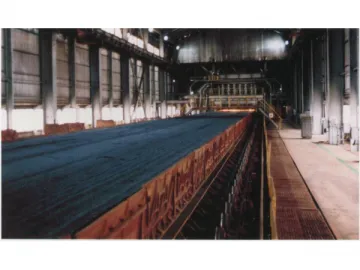

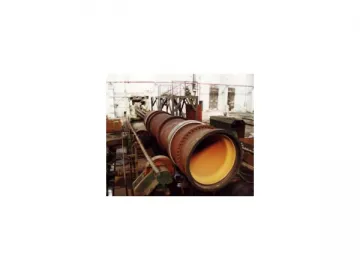

The hotmold methodcentrifugal casting machine is suitable for producing pipes with large diameters. It is widely used to produce ductile iron pipe with the length of 6000mmto 8000mmand the dimensions ranging from 1200mmto 2000mm and from 2000mmto 2600mm. These dimensions are set by the standards of ISO2531-1998(E) and GB13295-2003. The product features low manufacturing cost, reliable and steady function and easy operation.

Composition

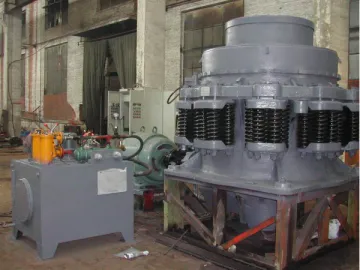

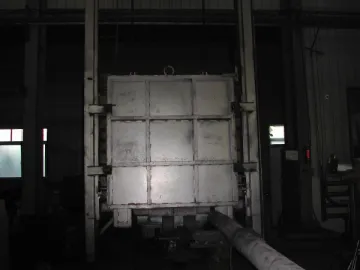

The hot mold method centrifugal casting machine is composed of centrifugal casting machine, spraying system, casting machine, hydraulic system, cooling system, and electric control system.

Technical Parameters

Specifications | Total Installed Capacity | Circulating Cooling Water Consumption | Compressed Air Consumption |

DN1200-2000 | 360KW | 20-60 m3/h | 1.5m3/min |

DN2000-2600 | 420KW | 60-100 m3/h | 2 m3/min |

Specification (DN) | 1200 | 1400 | 1500 | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 |

Average Output (Piece/h) | 30-32 | 32-35 | 35-38 | 36-40 | 38-42 | 40-45 | 42-50 | 45-52 | 50-55 |

Yate is a manufacturer of hot mold method centrifugal casting machine, spinning machine, based in China. We offer various types of products such as hot mold method centrifugal casting machine, spinning machine, and mold, the finishing line equipment, hydraulic pressure testing machine, counter pressure casting equipment, and so on. Our products are high quality and competitively priced. Our full chain of manufacturing mold, hydraulic pressure testing machine and bitumen coating machine, can be completed in China, even in one city. Our lower manufacturing cost can save your purchasing cost. A more detailed description of our product is shown on the page.

Links:https://globefindpro.com/products/104953.html