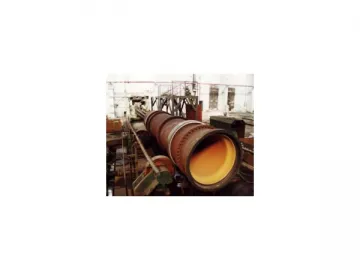

Rotary Kiln

Rotary Kiln

Hongxing rotary kiln is designed based on cutting-edge technologies, having reliable performance, high output and low cost.

Classifications and applications

A rotary kiln refers to a pyroprocessing device designed to raise materials to a very high temperature in a continuous process. It is also known as calcining kiln. According to the processed materials, the rotary kiln rotary kiln can be classified into cement kiln, lime kiln, metallurgy chemical kiln.

1. The cement kiln is used for the pyroprocessing stage of manufacture of various types of hydraulic cement, like Portland, and more. This type of rotary kiln is applicable for both dry process and wet process cement production.

2. Metallurgy chemical kiln is primarily used in metallurgy industries for oxidizing roasting of chromium ore, nickel ore, and iron ore, etc. and magnetic roasting of lean iron ore, and more. This rotary kiln is also regularly used for producing refractory materials and various aluminum materials as well as chemicals.

3. Lime kiln is commonly used in steel plants and ferroalloy plants for calcining active lime and caustic calcined dolomite, and more.

Technical specifications

Specification (m) | Kiln dimension | Production capacity (t/h) | Rotary speed (r/min) | Motor power (kw) | Total weight (t) | Remark | ||

Diameter (mm) | Length (mm) | Slope angle (%) | ||||||

φ1.4×33 | 1.4 | 33 | 3 | 0.9-1.3 | 0.39-3.96 | 18.5 | 47.5 | ---- |

φ1.6×36 | 1.6 | 36 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 52 | ---- |

φ1.8×45 | 1.8 | 45 | 4 | 1.9-2.4 | 0.16-1.62 | 30 | 78.2 | ---- |

φ1.9×39 | 1.9 | 39 | 4 | 1.65-3 | 0.29-2.93 | 30 | 77.59 | ---- |

φ2.0×40 | 2 | 40 | 3 | 2.5-4 | 0.23-2.26 | 37 | 119.1 | ---- |

φ2.2×45 | 2.2 | 45 | 3.5 | 3.4-5.4 | 0.21-2.44 | 45 | 128.3 | ---- |

φ2.5×40 | 2.5 | 40 | 3.5 | 9.0-10.5 | 0.44-2.44 | 55 | 149.61 | ---- |

φ2.5×50 | 2.5 | 50 | 3 | 6.25-7.4 | 0.62-1.86 | 55 | 187.37 | ---- |

φ2.5×54 | 2.5 | 54 | 3.5 | 6.9-8.5 | 0.48-1.45 | 55 | 196.29 | ---- |

φ2.7×42 | 2.7 | 42 | 3.5 | 10.0-11.0 | 0.10-1.52 | 55 | 198.5 | ---- |

φ2.8×44 | 2.8 | 44 | 3.5 | 12.5-13.5 | 0.437-2.18 | 55 | 201.58 | Suspension preheater kiln |

φ3.0×45 | 3 | 45 | 3.5 | 12.8-14.5 | 0.5-2.47 | 75 | 210.94 | ---- |

φ3.0×48 | 3 | 48 | 3.5 | 25.6-29.3 | 0.6-3.48 | 100 | 237 | Suspension preheater kiln |

φ3.0×60 | 3 | 60 | 3.5 | 12.3-14.1 | 0.3-2 | 100 | 310 | ---- |

φ3.2×50 | 3.2 | 50 | 4 | 40.5-42 | 0.6-3 | 125 | 278 | Suspension preheater kiln |

Hongxing is a rotary kiln manufacturer in China. In addition to rotary calcining kiln, we also manufacture jaw crusher, vibrating feeder, ball mill, and more. Our company is based in China, and the full chain of manufacturing stone crushing machinery and mineral processing equipment and other related products can be completed in China, even in one city, which helps save our production cost. Lower manufacturing cost saves your purchasing cost as well. The more details of each product are shown the page with description.

Links:https://globefindpro.com/products/104961.html

-

High Efficiency Concentrator

High Efficiency Concentrator

-

Sand Washer

Sand Washer

-

High Frequency Screen

High Frequency Screen

-

Table Concentrator

Table Concentrator

-

Chute Feeder

Chute Feeder

-

Bucket Elevator

Bucket Elevator

-

SS, Refractory Steel, Copper Bush Centrifugal Casting

Machine

SS, Refractory Steel, Copper Bush Centrifugal Casting

Machine

-

Mold for Copper Sleeve

Mold for Copper Sleeve

-

Dry Type Ball Mill

Dry Type Ball Mill

-

The Finishing Line Equipment

The Finishing Line Equipment

-

Blast Furnace

Blast Furnace

-

Hot Mold Method Centrifugal Casting Machine / Spinning Machine

Hot Mold Method Centrifugal Casting Machine / Spinning Machine