Automatic Metal Cutting Bandsaw, GZ Series

Automatic Metal Cutting Bandsaw, GZ Series

Automatic Metal Cutting Bandsaw GS4240/65

Features

1. This metal cutting bandsaw adopts double column structure.

2. It uses a worm gear reducer.

3. Hydraulic stepless speed regulation is adopted for cutting and feeding operations.

4. The saw frame can make a 45-degree turn clockwise for great flexibility.

Automatic Metal Cutting Bandsaw GS4248

Features

1. This metal cutting bandsaw is more compact as a result of the combination of guidepost and lift cylinder.

2. The saw frame can turn 45 degrees clockwise, making it easy to cut profile steel.

3. Accurate dial reading

4. The workpiece is hydraulically clamped.

Technical Specifications

Automatic Metal Cutting Bandsaw GZ4240

Model | GZ4240 |

Capacity(mm) | ●400■400×400 |

Blade Speed(m/min) | 20,33,48,75 |

Blade Size(mm) | 4650×41×1.3 |

Main Motor | 4KW |

Hydraulic Motor | 1.5KW |

Coolant Pump Motor | 90W |

Table Height | 610mm |

Workpiece Clamping | Hydraulically |

Blade Tensioning | Manually |

Floor Space(LxWxH)(mm) | 2400×1400×1900 |

Automatic Metal Cutting Bandsaw GZ4228

Model | GZ4248 |

Capacity(mm) | ●280■220×300 |

Blade Speed(m/min) | 22,48,70 |

Blade Size(mm) | 3850×34×1.1 |

Main Motor | 3KW |

Hydraulic Motor | 1.5KW |

Coolant Pump Motor | 90W |

Table Height | 610mm |

Workpiece Clamping | Hydraulically |

Blade Tensioning | Manually |

Floor Space(LxWxH)(mm) | 2000×2000×1300 |

Material

1. The saw blade is made using alloy steel imported from Germany.

2. The saw bow is constructed of high quality cast iron.

3. The table has undergone quenching treatment for high strength.

Maintenance

1. Before starting the automatic metal cutting bandsaw, please clean hydraulic oil tank, replace hydraulic oil, and lubricate rails, bearings and other parts in accordance with the requirements of lubrication system.

2. When starting the machine, first start hydraulic system. The bandsaw is allowed to perform cutting operation only after you have carefully checked it.

3. After operation, please loosen the band saw blades, which can extend their service life.

4. After operation, remove workpiece from the bandsaw machine, wipe coolant off the table, rails and clean chips from the machine. The saw frame should be lowered to the lowest position.

5. After work, turn off the power to prevent accidents.

Packaging

1. Wood packaging for export, according to customers’ specific suffocating requirements

2. Plywood packaging

Service

1. Our automatic metal cutting bandsaw comes with a one-year warranty, during which we can offer free spare parts if needed.

2. We will not compensate loss if the problem is caused by improper operation or other human errors.

Links:https://globefindpro.com/products/105055.html

-

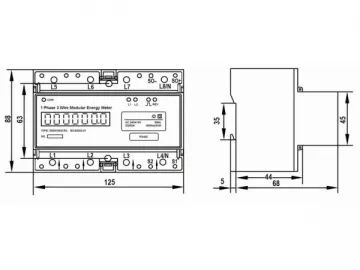

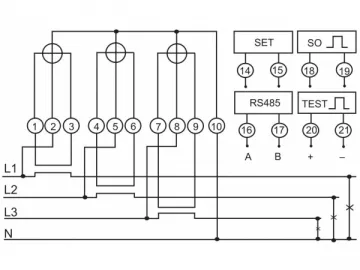

DDM100SCR3 DIN-rail Energy Meter With Communication Port, 7 Pole/Modular

DDM100SCR3 DIN-rail Energy Meter With Communication Port, 7 Pole/Modular

-

DSM866 Three Phase Electronic Energy Meter

DSM866 Three Phase Electronic Energy Meter

-

DMM862M Mechanical Energy Meter With Impulse Output

DMM862M Mechanical Energy Meter With Impulse Output

-

DSM228CF Single Phase Multi-tariff Electronic Energy Meter

DSM228CF Single Phase Multi-tariff Electronic Energy Meter

-

DMM862T3 (DT863) Mechanical Energy Meter

DMM862T3 (DT863) Mechanical Energy Meter

-

DSM866R Three Phase Electronic Energy Meter With Communication Port

DSM866R Three Phase Electronic Energy Meter With Communication Port

-

DDM30 DIN-rail Energy Meter, 1 Pole/Modular

DDM30 DIN-rail Energy Meter, 1 Pole/Modular

-

Swivel Metal Cutting Bandsaw, GS GP Series

Swivel Metal Cutting Bandsaw, GS GP Series

-

Pivot Metal Cutting Bandsaw, GY GB Series

Pivot Metal Cutting Bandsaw, GY GB Series

-

Frame Hydraulic Press

Frame Hydraulic Press

-

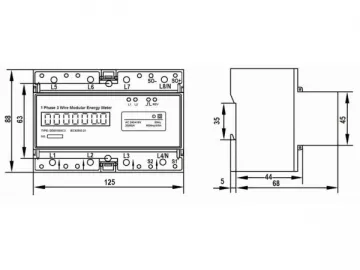

DDM100SC3 DIN-rail Energy Meter, 7 Pole/Modular

DDM100SC3 DIN-rail Energy Meter, 7 Pole/Modular

-

Hydraulic Swing Beam Shear, QC12Y Series

Hydraulic Swing Beam Shear, QC12Y Series