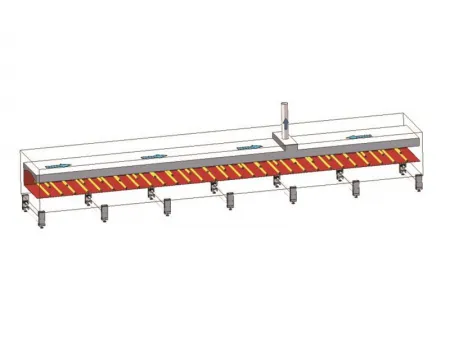

Pin Mill

Ideal for processing materials with a maximum Mohs hardness of 3 Ideal for processing materials with a maximum Mohs hardness of 3

Two pin discs move past each other at high speed

Fineness of the product adaptable by adjusting the rotating speed of the discs

Convenient to clean by opening the grinding door

Materials should not exceed a Mohs hardness of 3

No sieve design for smooth discharge and high productivity

Dual power available, offering low operating costs with linear speed up to 200 m/s for greater grinding force How it works Technical Parameters

Technical Parameters

Two pin discs move past each other at high speed

Fineness of the product adaptable by adjusting the rotating speed of the discs

Convenient to clean by opening the grinding door

Materials should not exceed a Mohs hardness of 3

No sieve design for smooth discharge and high productivity

Dual power available, offering low operating costs with linear speed up to 200 m/s for greater grinding force How it works

The feeding system feeds the materials evenly into the grinding chamber, exposing them to strong impacts from the high-speed rotating grinding discs. The materials are subjected to various forces, including friction, shearing, and collision between the static disc and gear ring, which leads to the grinding—depending on the properties of different materials, choosing from varying combinations of both discs so that it meets specific requirements for other materials.

| Parameter | 160 | 250 | 360 | 500 | 630 | 800 | 1000 |

| Coarse grinding disc diameter (mm) | 180 | 270 | 380 | 580 | 640 | 750 | 1000 |

| Coarse grinding disc rotate speed (r/min) | 9000 | 6000 | 4680 | 2480 | 2300 | 2150 | 1800 |

| Coarse grinding disc linear speed (m/s) | 84.8 | 84.8 | 93.1 | 75.3 | 77.1 | 84.4 | 94.2 |

| Coarse grinding power (kW) | 4 | 7.5 | 22 | 37 | 45 | 55 | 75 |

| Dual power (kW) | 22 30 | 2x55 | |||||

| Micronized grinding disc diameter (mm) | 160 | 260 | 360 | 520 | 630 | 730 | 1000 |

| Micronized grinding disc rotate speed (r/min) | 12000 | 7500 | 5550 | 3850 | 3200 | 2800 | 2050 |

| Micronized grinding disc linear speed (m/s) | 100.5 | 102.1 | 104.6 | 104.8 | 105.6 | 107.0 | 107.3 |

| Micronized grinding power (kW) | 4 | 7.5 | 22 | 37 | 55 | 75 | 90 |

| Max. air flow (m³/h) | 360 | 1000 | 2400 | 3200 | 5700 | 7500 | 10000 |

Note: The particle size, specific gravity, hardness, and moisture of raw materials are all closely associated to the production capacity. These parameters should only be used as a reference; for more detailed information please consult our engineers.

Album

Scan QR to Read

Links:https://globefindpro.com/products/1054.html

Links:https://globefindpro.com/products/1054.html

Recommended Products

Hot Products