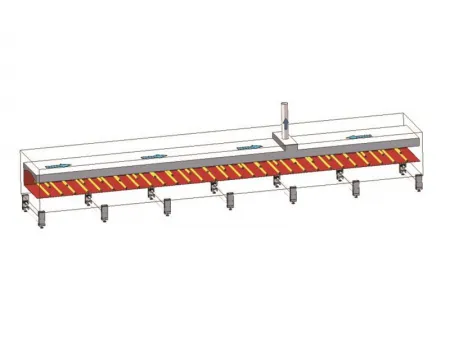

Hammer Mill

Easily replaceable wear parts, including moving hammers, grinding disc and cutter teeth Easily replaceable wear parts, including moving hammers, grinding disc and cutter teeth  Advantages Grinding particle size range D50: 10 ~ 850 μm

Advantages Grinding particle size range D50: 10 ~ 850 μm

Aperture of sieve 2-3 mm

Compact structure requiring minimal floor space, simple disassembly for cleaning purposes

Closed loop system with low dust and noise level

PLC control system, easy to operate

Low installed power with wide application range and high cost performance A belt can be used as an effective solution for powering machines when the renowned motor brands do not provide high-speed motors

Explosion-proof design available for processing flammable and explosive materials

Offer designs for high, low and normal temperatures, with air closed circulation and inert gas circulation to meet the temperature requirements of various materials Technical Parameters

Album

ALPA’s Hammer Mill is an ideal choice for chemical, inorganic salt production, medicine, food, pigment and dye-making, pesticide, battery material, mineral refining and refractory material production and other industries.

How it worksThe feeding system evenly distributes the materials into the grinding chamber, where they are exposed to a strong impact from the high-speed rotating grinding moving disc. The combination of friction, shearing and collision between the static disc and gear ring creates comprehensive forces that grind the materials. Depending on specific material properties, different combination of both discs can be used.

Aperture of sieve 2-3 mm

Compact structure requiring minimal floor space, simple disassembly for cleaning purposes

Closed loop system with low dust and noise level

PLC control system, easy to operate

Low installed power with wide application range and high cost performance A belt can be used as an effective solution for powering machines when the renowned motor brands do not provide high-speed motors

Explosion-proof design available for processing flammable and explosive materials

Offer designs for high, low and normal temperatures, with air closed circulation and inert gas circulation to meet the temperature requirements of various materials Technical Parameters

| Parameter | CUM-160F | CUM-250F | CUM-360F |

| Grinding disc diameter (mm) | 150 | 250 | 350 |

| Max. rotate speed (r/min) | 12000 | 7500 | 5550 |

| Power (kW) | 3~4 | 5.5~7.5 | 11~15 |

| Grinding fineness (mesh) | 20~325 | 20~325 | 20~325 |

| Production capacity (kg/h) | 5~50 | 15~200 | 25~500 |

Scan QR to Read

Links:https://globefindpro.com/products/1055.html

Links:https://globefindpro.com/products/1055.html

Recommended Products

-

Cooling & Stacking

Cooling & Stacking

-

Semi-automatic Box Stitching Machine

Semi-automatic Box Stitching Machine

-

Vertical Dough Mixer

Vertical Dough Mixer

-

Dough Feeder

Dough Feeder

-

Electric Tunnel Oven

Electric Tunnel Oven

-

Gravure Printing Press, SAY1300C4

Gravure Printing Press, SAY1300C4

-

Pin Mill

Pin Mill

-

SE Series Slew Drive

SE Series Slew Drive

-

ARC MMA Welder / Inverter Welder

ARC MMA Welder / Inverter Welder

-

No-clean Solder Flux, JF-SP726(For Solar Photovoltaic Application)

No-clean Solder Flux, JF-SP726(For Solar Photovoltaic Application)

-

Vibration Mill

Vibration Mill

-

Ring Roller Mill

Ring Roller Mill

Hot Products