Hot Stamping Machine B.T-168S

.Micro-processor controlling, pneumatic units driving;

2.Stamping pressure, temperature and time adjustable;

3.Worktable could be adjustable for forth/back move, easy and safe operation;

4.Worktable coulbe be adjustable for its forth/back, left/right position, as well as turned slightly;

5.Auto and adjustable paper feeding, collection;

6.According to different height of various substrates, stamping height adjustment through turning handwheel and stamping stroke adjustment by turning knob;

7.Available for bend and cylindrical substance printing; dismantle shuttle table for flat printing.

[6] Hot Stamping Machine B•T-168S

These products are widel used in cosmetics tube,toothpaste tube,pharmaceutical tube and food industries tube ,etc.

[6] Hot Stamping Machine B•T-168S

Max. stamping pressure: 1274N;

Max. stamping height: 95mm;

Size of stamping plate: 100mm×168mm;

Stamping temperature adjustable range: 0-280℃;

Heating wattage: 900W;

Stamping foil winding length: ≤200 mm;

Max. stamping speed: 1000pcs/hr;

Air consumption: 58Litre/min;

Power: 220V/50Hz;

Outline dimension: 630×580×1385mm;

Weight: 108Kg.

Links:https://globefindpro.com/products/105492.html

-

Filling And Sealing Machine B.GFN-100

Filling And Sealing Machine B.GFN-100

-

Inner-Heating Filling And Sealing Machine B.GFN-30

Inner-Heating Filling And Sealing Machine B.GFN-30

-

Tube Capping Machine YGR17

Tube Capping Machine YGR17

-

Base Color Printing Machine ZDO7B

Base Color Printing Machine ZDO7B

-

UV Varnishing Machine

UV Varnishing Machine

-

Filling And Sealing Machine B.GF-40-2

Filling And Sealing Machine B.GF-40-2

-

Latexing Machine WT01

Latexing Machine WT01

-

Chiller

Chiller

-

Printing Dried Oven YGR16C

Printing Dried Oven YGR16C

-

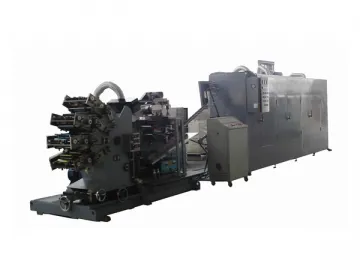

Six Color Rotary Printer B.YS-6

Six Color Rotary Printer B.YS-6

-

Four Color Rotary Printer B.YS-4 (UV System)

Four Color Rotary Printer B.YS-4 (UV System)

-

Flame Treatment Machine B.HY-300HCA

Flame Treatment Machine B.HY-300HCA