Double-Layer Co-Extrusion Stretch Film Making Machine

Double-Layer Co-ExtrusionStretch Film Making Machine

Use

The double-layer co-extrusion stretch film making machineuses LDPE and LLDPE to produce cast stretch film, which is widely applied topackaging for building material, auto parts, hardware parts etc.

With shrinking memory function and being self-sticky,the film can make goods securely packaged to prevent goods from loosening andcollapsing during transportation and being populated by dust. The transparencyand tensile strength of the film can make the packaging beautiful, economicaland practical. The plastic film can be widely used in wrapping of palletizedgoods and is a good substitute for hot shrinking packaging film duringtransportation.

Features

BL-500/1000automatic double-layer co-extrusion stretch film making machine features lownoise, stable running, with the winding part controlled by PLC program andfunctions of automatic cutting, winding, and roll changing.

Optional Equipment

1. Auto loader

2. Auto dry hopper

3. Electric net changer

4. Hydraulic net changer

5. Air shaft

6. Glue pump

Main Technical Variables

| Model | BL-500 (double-layer co-extrusion) | BL-1000 (double-layer co-extrusion) |

| Diameter of screw stem | 55mm*2 | 65mm*2 |

| Screw ratio (L/D) | 28:1(L/D) | 28:1(L/D) |

| Rotational speed of screw stem | 10-120rpm | 10-120rpm |

| Folding width of products | 200-500mm | 1000(500*2)mm |

| Thickness | 0.015-0.05mm | 0.015-0.05mm |

| Main motor power | 15kw*2 | 18.5kw*2 |

| Heating power | 30kw | 50kw |

| Max. output (kg/h) | 40 | 100 |

| Machine weight | 3T | 5.5T |

| Overall dimension(L*W*H)mm | 4500*2600*2550 | 7500*4500*3200 |

As a professional double-layer co-extrusion stretchfilm making machine manufacturer in China, we also offer soft handlesealing machine, label slitting rewinding machine, color mixer, plasticrecycling granulator, etc.

Links:https://globefindpro.com/products/106639.html

-

High Speed Bag Making Machine

High Speed Bag Making Machine

-

Double Layer Bag Making Machine

Double Layer Bag Making Machine

-

Stretch Film Rewinding Slitter

Stretch Film Rewinding Slitter

-

Multifunctional Plastic Bag Making Machine

Multifunctional Plastic Bag Making Machine

-

Heat Sealing Heat Cutting Bag Making Machine / Bottom Sealing Bag Making Machine

Heat Sealing Heat Cutting Bag Making Machine / Bottom Sealing Bag Making Machine

-

Automatic Non-Woven Bag Making Machine

Automatic Non-Woven Bag Making Machine

-

Stack Flexographic Label Printing Press

Stack Flexographic Label Printing Press

-

High Speed Letterpress Printing Machine

High Speed Letterpress Printing Machine

-

Hand Feeding Preform Automatic Blow Molding Machine

Hand Feeding Preform Automatic Blow Molding Machine

-

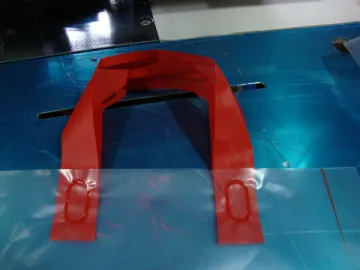

Soft Handle Sealing Machine

Soft Handle Sealing Machine

-

Three Layer Film Blowing Machine

Three Layer Film Blowing Machine

-

Double-Color Flexographic Printing Machine / Non-Woven Fabric Printing Machine

Double-Color Flexographic Printing Machine / Non-Woven Fabric Printing Machine