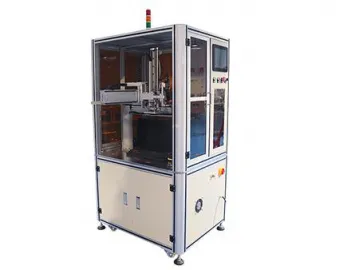

AS-P02 Top Labeling Machine (Bags and Cards Separating)

Our top labeling machine was developed for the application of self-adhesive labels on flat surfaces of various products including books, PE bags, cartons, scratch cards, and much more.

This labeling machine can be equipped with a single labeling head, two labeling heads, multiple labeling heads, and automatic separating equipment to apply labels on different horizontal positions of the same product. It also supports automatic collation.

Applications

Applicable labels: self-adhesive label, self-adhesive film, electronic supervision code, bar code, etc.

Applicable products: products with flat surfaces and large curved surfaces.

Samples

Specification

| Model | AS-P02 |

| Label stop accuracy | ±1mm |

| Production speed | 40-400 pcs/min |

| Product length | 40mm~280mm |

| Product width | 40mm~200mm |

| Product height | 0.2mm~2mm |

| Label length | 6mm~250mm |

| Label roll inside diameter | Φ76mm |

| Label roll outside diameter | Φ280mm |

| Dimensions (length x width x height) | 2200mm x 700mm x 1400mm |

| Weight | 180Kg |

Details of Top Labeling System

Photoelectric sensor:

The labeling machine is equipped with a high-quality photoelectric sensor made by Sick which features high precision and high reliability.

Touch screen:

Controlled by PLC, the interface is convenient to use. With just a tap of its touch screen, you can easily access various functions and parameters for your product needs.

Automatic separating equipment:

It is designed to separate the workpiece so as to minimize labor costs and improve overall productivity.

Adjustable seat: The 6DOF adjustable seat enables quick changeover between different products.

Automatic receiving device: It collects the labelled products.

Scan QR to Read

Links:https://globefindpro.com/products/10821.html

Links:https://globefindpro.com/products/10821.html

Recommended Products

-

AS-S05 Automatic Labeling Machine, Integrated side and warp around labeling

AS-S05 Automatic Labeling Machine, Integrated side and warp around labeling

-

AS-R03 Print and Apply Labeling System (Labeling on Cartons)

AS-R03 Print and Apply Labeling System (Labeling on Cartons)

-

AS-S13 Semi-Automatic Labeler (Front and Back Labeling)

AS-S13 Semi-Automatic Labeler (Front and Back Labeling)

-

AS-S01 Side Labeling Machine

AS-S01 Side Labeling Machine

-

AS-R02 Print and Apply Labeling System (Labeling and Coding for Logistics)

AS-R02 Print and Apply Labeling System (Labeling and Coding for Logistics)

-

AS-A21D Print and Apply Labeling System (Labeling on Drum/Barrel)

AS-A21D Print and Apply Labeling System (Labeling on Drum/Barrel)

-

AS-P16 Semi-automatic labeler (Wrap Around Labeling/ For Round and Multi-sides Bottles)

AS-P16 Semi-automatic labeler (Wrap Around Labeling/ For Round and Multi-sides Bottles)

-

AS-P05 Inline Labeling Machine with Multi labeling head

AS-P05 Inline Labeling Machine with Multi labeling head

-

AS-R01 Print and Apply Labeling System (Labeling on Wooden Sheet)

AS-R01 Print and Apply Labeling System (Labeling on Wooden Sheet)

-

AS-P08 Inline Labeling Machine

AS-P08 Inline Labeling Machine

-

Rubber Cracker Mill

Rubber Cracker Mill

-

Rubber Tyre Cutter

Rubber Tyre Cutter

Hot Products