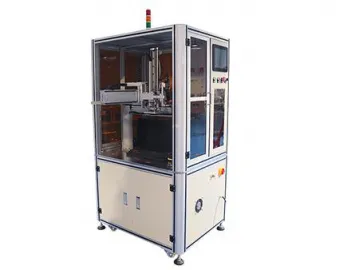

AS-S01 Side Labeling Machine

The side labeling machine is suitable for the application of labels to single sides of flat bottles, round bottles, and square bottles. It features a maximum production speed of 200 pcs/min.

Applications

Applicable labels: self-adhesive label, self-adhesive film, electronic supervision code, bar code, etc.

Applicable products: products with flat surfaces, large curved side surfaces, round surfaces, etc.

Applicable industries: pharmaceutical, cosmetics, electronics, hardware, plastic, etc.

Samples

Specification

Details of Automatic Single-Side Labeling System

Touch screen:

It is controlled by PLC. The interface is very convenient to use. With just a tap of its touch screen, you can easily access various functions and parameters according to your product needs.

Guide mechanism:

It is used to adjust the position of workpieces of various sizes using joints and bars.

Bottle dividing mechanism:

It controls the speed of the motor to create appropriate gaps among the bottles to ensure each bottle has sufficient time to be labelled.

Label adjusting mechanism:

Label position, height, and angle can be adjusted by the label adjusting mechanism. It enables the label to be applied to bottles with different shapes and sizes with great accuracy.

Applications

Applicable labels: self-adhesive label, self-adhesive film, electronic supervision code, bar code, etc.

Applicable products: products with flat surfaces, large curved side surfaces, round surfaces, etc.

Applicable industries: pharmaceutical, cosmetics, electronics, hardware, plastic, etc.

Samples

Specification

| Model | AS-S01 |

| Label stop accuracy | ±1mm |

| Production speed | 30-200 pcs/min |

| Product diameter | φ20mm~φ250mm |

| Product width | 30mm~90mm |

| Product height | 60mm~280mm |

| Label length | 20mm~100mm |

| Label roll inside diameter | Φ76mm |

| Label roll outside diameter | Φ280mm |

| Dimensions (length x width x height) | 3000mm x 1450mm x 1600mm |

| Weight | 350Kg |

Details of Automatic Single-Side Labeling System

Touch screen:

It is controlled by PLC. The interface is very convenient to use. With just a tap of its touch screen, you can easily access various functions and parameters according to your product needs.

Guide mechanism:

It is used to adjust the position of workpieces of various sizes using joints and bars.

Bottle dividing mechanism:

It controls the speed of the motor to create appropriate gaps among the bottles to ensure each bottle has sufficient time to be labelled.

Label adjusting mechanism:

Label position, height, and angle can be adjusted by the label adjusting mechanism. It enables the label to be applied to bottles with different shapes and sizes with great accuracy.

Scan QR to Read

Links:https://globefindpro.com/products/10825.html

Links:https://globefindpro.com/products/10825.html

Recommended Products

-

AS-R02 Print and Apply Labeling System (Labeling and Coding for Logistics)

AS-R02 Print and Apply Labeling System (Labeling and Coding for Logistics)

-

AS-A21D Print and Apply Labeling System (Labeling on Drum/Barrel)

AS-A21D Print and Apply Labeling System (Labeling on Drum/Barrel)

-

AS-Z1R01 Print and Apply Labeling System (Labeling on Woven Bags)

AS-Z1R01 Print and Apply Labeling System (Labeling on Woven Bags)

-

AS-C12A Semi-automatic Labeler with Code Printer

AS-C12A Semi-automatic Labeler with Code Printer

-

AS-A11D4 Print and Apply Labeling System (Top Labeling)

AS-A11D4 Print and Apply Labeling System (Top Labeling)

-

AS-S06 Inline Labeling Machine

AS-S06 Inline Labeling Machine

-

AS-S13 Semi-Automatic Labeler (Front and Back Labeling)

AS-S13 Semi-Automatic Labeler (Front and Back Labeling)

-

AS-R03 Print and Apply Labeling System (Labeling on Cartons)

AS-R03 Print and Apply Labeling System (Labeling on Cartons)

-

AS-S05 Automatic Labeling Machine, Integrated side and warp around labeling

AS-S05 Automatic Labeling Machine, Integrated side and warp around labeling

-

AS-P02 Top Labeling Machine (Bags and Cards Separating)

AS-P02 Top Labeling Machine (Bags and Cards Separating)

-

AS-P16 Semi-automatic labeler (Wrap Around Labeling/ For Round and Multi-sides Bottles)

AS-P16 Semi-automatic labeler (Wrap Around Labeling/ For Round and Multi-sides Bottles)

-

AS-P05 Inline Labeling Machine with Multi labeling head

AS-P05 Inline Labeling Machine with Multi labeling head

Hot Products