Corn Curls Processing Line

Corn Curls Processing Line

Corn curls machine

Our Corn Curls Processing Line uses small particles of corn as raw material. After being expanded by the main engine, they can be made into irregular kurkure. Crisp food with different flavors can be achieved by seasoning. Crunchy and great in taste, kurkure are made by extrusion process.

The Kurkure corn meal is moisturized in the flour mixer with water then fed to the rotary die extruder. While in the extruder, the excess heat and pressure from the screws heats the meal and reduces the moisture content. The meal passes through the die and gets cut by the cutting knives into the required lengths. The Kurkure are fried in cooking oil then cooled before flavoring. To improve their taste, seasoning is sprayed on the Kurkure.

Machines involved in making Kurkure

a, Flour Mixer

Mixes corn meal with water to prepare the flour for Kurkure

b, Rotary Die Extruder

Cooks the corn meal and extrudes the Kurkure from the die. The Rotary Die twists and curls the meal before extruding, giving a uniform texture.

c, Automatic Frying Machine

Fries the Kurkure in hot cooking oil. Frying makes the Kurkure taste crunchy

d, Cooling Conveyor

Cools the fried Kurkure and reduces the temperature before packing

e, Automatic Seasoning System

Adds required seasoning to the fried and cooled Kurkure giving them different flavors.

f, Automatic Packaging Machine

Packs the Kurkure into attractive printed pouches

Specifications

| Parameter | DLG76 |

| Installed capacity | 20 kw |

| Output | 150 kg/h |

| Dimension | 21x2.5x4m |

Through our consistent efforts, and over seven years of experience and dedicated staff, we provide a high quality corn curls processing line at an economical price. To better satisfy various customer needs, we also produce a corn flakes processing line, a baby food processing line, a bread crumb processing line, etc. If you have a need for our products, please feel free to contact us via email or at the address listed on this website. We look forward to working with you.

Links:https://globefindpro.com/products/110709.html

-

SMJL-SMJJ(Naked-Insulated Cable)insulated Joint Pipe

SMJL-SMJJ(Naked-Insulated Cable)insulated Joint Pipe

-

Insulated Ring Terminal

Insulated Ring Terminal

-

SMJY(Different Diameter)Pre-insulated Joint Pipe

SMJY(Different Diameter)Pre-insulated Joint Pipe

-

Insulated Spade Terminal

Insulated Spade Terminal

-

Core Filled Snack Food Processing Line

Core Filled Snack Food Processing Line

-

SMJT(Same-diameter)Pre-insulated Joint Pipe

SMJT(Same-diameter)Pre-insulated Joint Pipe

-

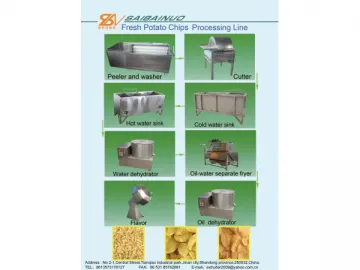

Fresh Potato Chips Processing Line

Fresh Potato Chips Processing Line

-

Modified Starch Processing Line

Modified Starch Processing Line

-

Mixer

Mixer

-

Single Screw Extruder

Single Screw Extruder

-

Snack Food Processing Line

Snack Food Processing Line

-

Acrylic Laser Cutting Machine 100SA, 100SAII

Acrylic Laser Cutting Machine 100SA, 100SAII