Die Cast Machining Service

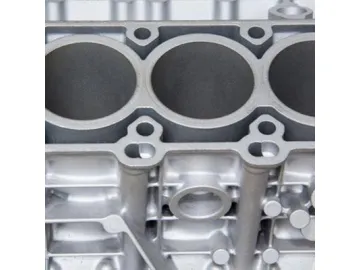

The metal part made by die casting usually have a rough surface which cannot be used directly for customers. We are capable of various processing methods to solve these problems properly, such as drilling, tapping or numerical control machining. Machining can remove round edges and loose flash of die castings. Different die cast parts need different machining services. Equipped with advanced CNC machines, we can produce the complex parts with better dimensional accuracy and consistency.

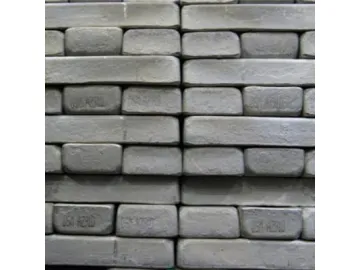

Aluminum alloys are always preferable to being die cast materials, of which aluminum alloy 380 is quite ideal for machining. In this process, high-speed steel tools are commonly used, because the tools with high clamping forces cause the dimensional variations easily.

It is also effective to use the same method to machine magnesium alloy. However, due to lower resistance to cutting and relatively lower heat capacity of magnesium alloy, the tools with smooth surfaces and sharp cutting edges are needed during the process.

Machining Services Available for Your NeedsWe can strategically combine several machining methods together to offer the most suitble machining service for your design requirements. A comprehensive series of machining services are available, including but not limited to:

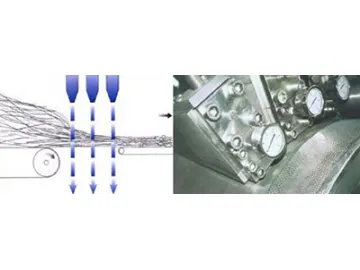

Multi-Point Drilling

Multi-Point Tapping

Milling

Boring

Lathe and Turning

Our machining includes but is not limited to:

Three(3) 3-axis CNC Machining Centers

Two(2) 4-axis CNC Machining Centers

Twenty-two(22) CNC Lathes

Four(4) Vertical Drilling Machines

Links:https://globefindpro.com/products/11474.html