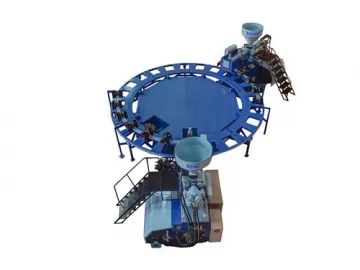

Single Colour Sole Injection Moulding Machine, LA106U T/ LA112U T

| Item | Unit | LA106U T | LA112U T |

| Raw materials | TPU, TR, TPR, PVC | ||

| Stations | 6 | 12 | |

| Screw diameter | mm | 60 | |

| Maximum injection volume | CC | 565 | |

| Injection pressure | MPa | 120 | |

| Clamping force | Tons | 150 | |

| Yield | Pairs/hour | 60-150 | 100-240 |

| Mould space | mm | 500*330*200 | |

| Heating power | kW | 9 | |

| Total power | kW | 34.5 | |

| Dimensions | cm | 480*210*250 | 550*310*250 |

| Machine weight | Tons | 7.3 | 7.8 |

| Oil consumption | L | 650 | |

| Special configuration | Servo motor, automatic mould manipulator, mould water cooling system, drying hopper | ||

V type mould structure

Drying hopper

Mould manipulator

Energy-saving hydraulic servo control system

System flow chart LA106U T/ LA112U T Single Colour Sole Injection Moulding Machine

This injection moulding machine is used for the production of monochromatic studs, soles, shoe covers and mobile phone cases. It is applicable to turn out goods from different materials, like TPU, TR, PVC and TPR.

PLC system with industrial human-machine interface (HMI), easy to use;

PLC system

PLC

HMI interface

Besides these features, our injection moulding machine is produced with following designs:

Safety sign

Safety signSafety door with photoelectric switch

Emergency stop button

Rotary table anti-lifting switch

Auxiliary Equipment

Cooling tower

it brings down the temperature of hydraulic oil and raw materials;

Crusher

it breaks down used materials;

Vertical mixer

it blends materials with different colours and turn them into one colour;

Accessories and Components

| Parts list | ||

| Toolbox | / | 1pc |

| Allen key | 1.5-10 | 9 sets |

| Open-end wrench | 6-24 | 8 sets |

| Phillips screwdriver (small) | / | 2pcs |

| Phillips screwdriver (large) | / | 1pc |

| Adjustable wrench | 250mm | 1pc |

| Heating ring | Ø120*80 mm | 2pcs |

| Heating ring | Ø70*50 mm | 1pc |

| Heating rod | Ø15.8*100 mm | 2pcs |

| Proximity switch | Ø 25*25mm | 1pc |

| Proximity switch | Ø 12*12mm | 1pc |

| Thermoelectric coupling | K type/5M | 2pcs |

| Oil seal | / | 2pcs |

| Plugging rod | / | 1pc |

| Plugging bushing | / | 1pc |

| Copper gasket | / | 1pc |

| Injection nozzle | / | 1pc |

| User manual | / | 1 |

Tags automatic shoe machine

PVC injection moulding machinery

Links:https://globefindpro.com/products/1344.html

-

Single Colour Sole Injection Moulding Machine, LA110U/LA120U

Single Colour Sole Injection Moulding Machine, LA110U/LA120U

-

Cold Applied Insulation Boot

Cold Applied Insulation Boot

-

Two Colour Sole Injection Moulding Machine, EB220R/EB224R

Two Colour Sole Injection Moulding Machine, EB220R/EB224R

-

Inner Cone Plug-In Termination

Inner Cone Plug-In Termination

-

All-In-One Portable Endoscope Camera System, INP-Y300

All-In-One Portable Endoscope Camera System, INP-Y300

-

Medical LED Cold Light Source, INP-LUM200

Medical LED Cold Light Source, INP-LUM200

-

SC-A120A LED Under Cabinet Light, 3W COB Recessed LED Downlight

SC-A120A LED Under Cabinet Light, 3W COB Recessed LED Downlight

-

Medical Endoscope Camera Module

Medical Endoscope Camera Module

-

Aluminum Foil Cartoning Machine

Aluminum Foil Cartoning Machine

-

Medical LED Cold Light Source Module

Medical LED Cold Light Source Module

-

SC-D102A Rigid LED Strip, Waterproof LED Light Bar

SC-D102A Rigid LED Strip, Waterproof LED Light Bar

-

Endoscope Zoom Coupler

Endoscope Zoom Coupler